Welding defects

Welding Defects:-

- Hot cracks

- Cold cracks/Delayed cracks

- Porosities

- Lack of fusion

- Incomplete/excess penetration

- Undercut

- Slag/ Inclusion

- Mismatch

- Burn through

- Root Cavity

- Caters

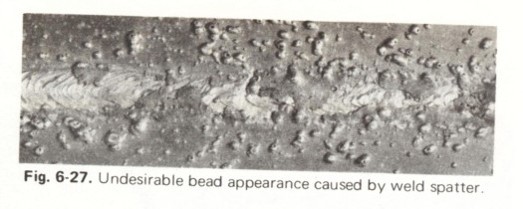

- Spatters

What is Meaning of Defect:-

A defect is a reject able discontinuity, which occurs in an amount great enough to render a particular object or structure unsuitable for its intended service based on criteria in the applicable code.

Classification of Defects:-

1) Planar defects / Two dimensional defects — E.g. cracks, lack of fusion, lack of penetration, are crtical in nature and are not tolerated to any extent.

2) Voluminal defects / Three dimensional defects — E.g. slag inclusion, cavities, porosities, etc are tolerated to a certain extent depending on the product class and applicable code.

3) Geometric defects– E.g. excess reinforcement, underfill, root suck back, distortion are also permitted to a certain extent.