Steam Turbine Lubrications

Lubrication:-

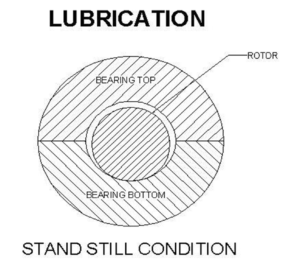

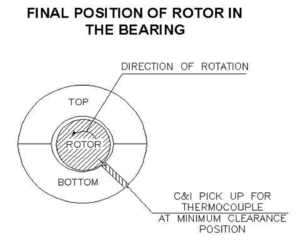

Turbine bearings are hydro dynamically Lubricated. For this to happen following things are important

- Viscosity of oil which is directly related to the oil Temperature.

- Rotation/speed of the Rotor.

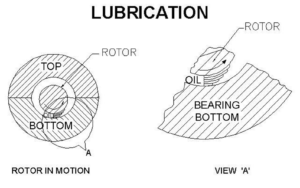

- Desired Clearances/Converging Wedge in the Bearings. (convergence should be in the direction of rotation)

In fact the Pressure of the Lube oil is mainly just to ensure that oil reaches the Bearing. However it is also very important and requires to be maintained as per design.

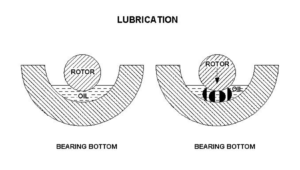

- As rotor rotates at low speed ,initially there is no film lubrication but as its speed increases there is conversion of boundary layer lubrication into Film lubrication.

- From zero speed to appx. 540 RPM there is no continues film between rotor and bearings and there is chance of rubbing between rotor and Bearing. Therefore JOP is used to prevent the contact between rotor and bearings.

- At Above 540 RPM the JOP can be Switched off, as film lubrication comes into picture.

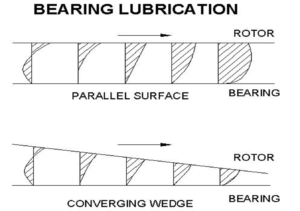

- It is to be noted that when the surfaces are parallel the volume flow rate at inlet is less than the outlet flow rate and film can’t sustain.

- Therefore for a stable film, area needs to be convergent to ensure equal volume flow throughout the length.

- The minimum clearance depends upon following

– Viscosity of oil

– Speed of Rotor

– Load on the rotor

TYPE OF BEARINGS

- Cylindrical Bearing( Single wedge ring) This has single oil inlet.

- Elliptical Bearing( Double wedge bearing) This has double oil inlet.

- Segment Bearing( Multi wedge Bearing).

VARIOUS FUNCTIONS OF OIL

- Lubrication and cooling of Bearing.

- Jacking up the shaft and to provide hydrostatic lubrication during low speed operation through J.O.P.

- Supply of control oil to governing and protection system,

- Supply of control oil to LP by pass governing.

- As a Sealing Agent in Hydrogen Cooled Generator

MAIN COMPONENNTS OF TURBINE LUBRICATION SYSTEM

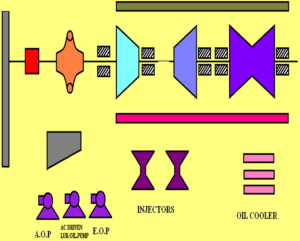

- Main oil pump (M.O.P)

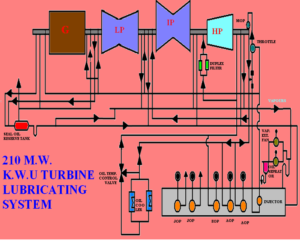

- Auxiliary oil pump (A.O.P) –In KWU T.G

- A.C. driven lub oil pump

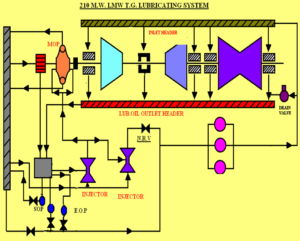

- Starting oil pump (S.O.P)-In LMW T.G

- Emergency oil pump (E.O.P)

- Main oil tank (M.O.T)

- Oil pressure drop relay (O.P.D.R)

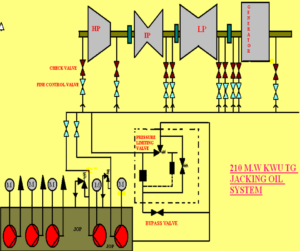

- Jacking oil pump (J.O.P)

- Oil Cooler

- Oil Filter

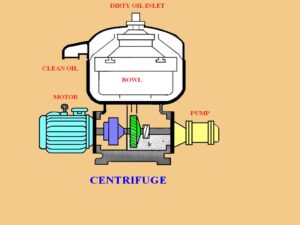

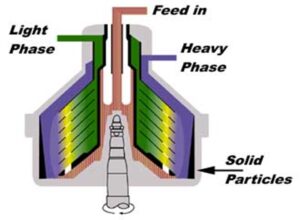

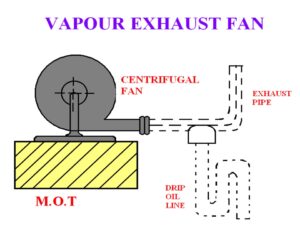

- Centrifuge and vapor Extraction system

- Centrifuge:-

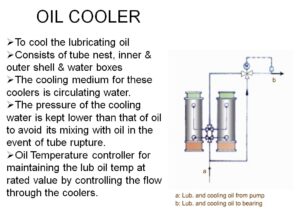

Oil Cooler:-

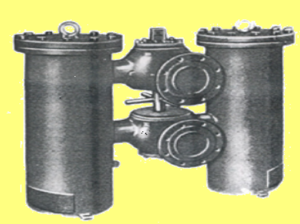

OIL FILTERS:-

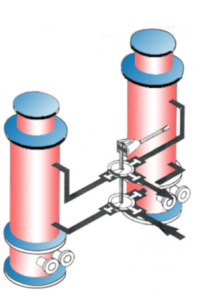

DUPLEX OIL FILTER WITH CHANGEOVER DEVICE:-

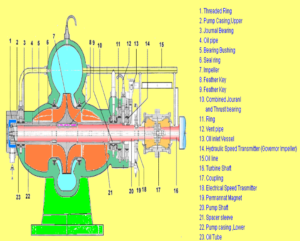

MAIN OIL PUMP(MOP)

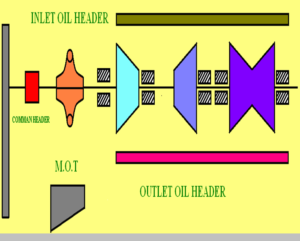

- LOCATION: This pump is mounted in the front bearing pedestal. It is coupled with turbine rotor through a gear coupling.

- Oil suction from MOT Through two number of injectors connected in series.

- Takes over when turbine speed > 2800 rpm.

- Supplies oil for turbine bearing lubrication as well as for the turbine governing system.

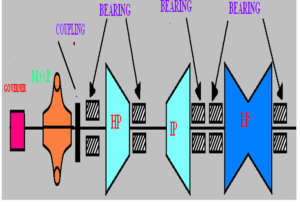

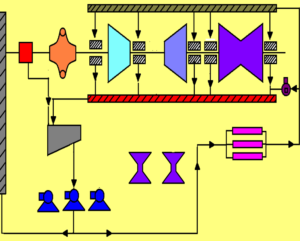

LMW TG LUBRICATING SYSTEM

( BEARING, M.O.P, GOVERNOR, COUPLING)