STEAM TRAPS

1.) Def: It is a valve Device that discharges condensate and air from the steam lines without discharging the steam.

In order to obtain the fast heating of the product and equipment.

2.) Functions:

Discharge condensate as soon it is formed.

Does not allow steam to escape.

Must discharge air and other incondensable gases

3.) Types of Steam Traps

A.) Mechanical:

It is operated by changes in fluid density.

B.) Thermodynamic:

It is operated by the changes in fluid Dynamics.

C.) Thermostatic:

It is operated by changes in fluid Temperature.

A.) Mechanical Steam Trap (Inverted Bucket Trap)

Advantages:

Can withstand high pressures

Tolerates water hammer

Suited for superheated steam lines

Safer because failure mode is open

Disadvantages:

Trap body must always have enough water

Water seal loss by De-superheated steam

Can be damaged by freezing

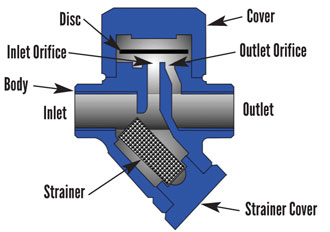

B.) Thermodynamic Steam Trap

C.) Thermostatic Steam Trap

4.) Points to be kept in mind while installing Steam Traps

Water hammer:

Condensate picked up by moving steam

Can damage steam trap

Continuous slope in flow direction reduces this

Dirt:

Affects steam trap performance

Strainers:

Helps to remove dirt

Steam locking:

Can occur in rotating machinery

Only float trap has ‘steam lock release’ valve

Pipe sizing:

Correct pipe size – traps affected by resistance to flow

Avoid pipe fittings close to trap – back pressure risk

Air venting:

Important for system warm up and operation

5.) Performance Assessment of Steam Traps

Visual Testing

Sound Testing – Ultrasonic Leak detectors

Temperature Testing – Temperature Guns, Thermal Chalks