Steam distribution system Components

Most important components

1.Pipes

2.Drain points

3.Branch lines

4.Strainers

5.Filters

6.Separators

7.Steam traps

8.Air vents

9.Condensate recovery system

10.Insulation

1.Pipes

- Pipe material: carbon steel or copper

- Correct pipeline sizing is important

- Oversized pipework:

- Higher material and installation costs

- Increased condensate formation

- Undersized pipework:

- Lower pressure at point of use

- Risk of steam starvation

- Risk of erosion, water hammer and noise

- Size calculation: pressure drop or velocity

- Pipeline layout: 1 m fall for every 100 m

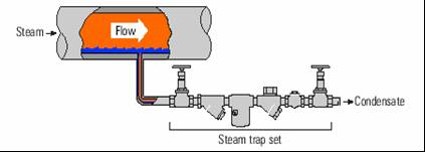

- Drain points

- Ensures that condensate can reach steam trap

- Consideration must be give to

- Design

- Location

- Distance between drain points

- Condensate in steam main at shutdown

- Diameter of drain pipe

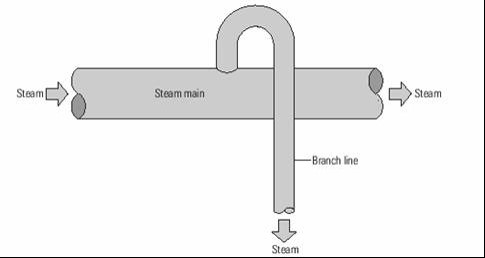

- Branch lines

- Take steam away from steam main

- Shorter than steam mains

- Pressure drop no problem if branch line < 10 m

Branch line connections

- Top: driest steam

- Side or bottom: accept condensate and debris

- Drop leg: low point in branch line

- Sometime steam runs across rising ground

- Condensate should run against steam flow