Steam distribution system components

- Steam traps

- What is a steam trap?

- “Purges” condensate out of the steam system

- Allows steam to reach destination as dry as possible

- Steam traps must handle variations in

- Quantity of condensate

- Condensate temperature

- Pressure (vacuum to > 100 bar)

Selection depends on steam trap’s ability to

- Vent air at start-up

- Remove condensate but not steam

- Maximize plant performance: dry steam

Steam traps – considerations

Water hammer

- Condensate picked up by moving steam

- Can damage steam trap

- Continuous slope in flow direction reduces this

Dirt

- Affects steam trap performance

Strainers

- Help remove dirt and cheaper than maintaining steam traps

Steam locking

- Can occur in rotating machinery

- Only float trap has ‘steam lock release’ valve

Diffusers

- Installed to end of the pipe

- Reduces sound and ferocity of flash steam discharge

Pipe sizing

- Correct pipe size – traps affected by resistance to flow

- Avoid pipe fittings close to trap – back pressure risk

Air venting

- Important for system warm up and operation

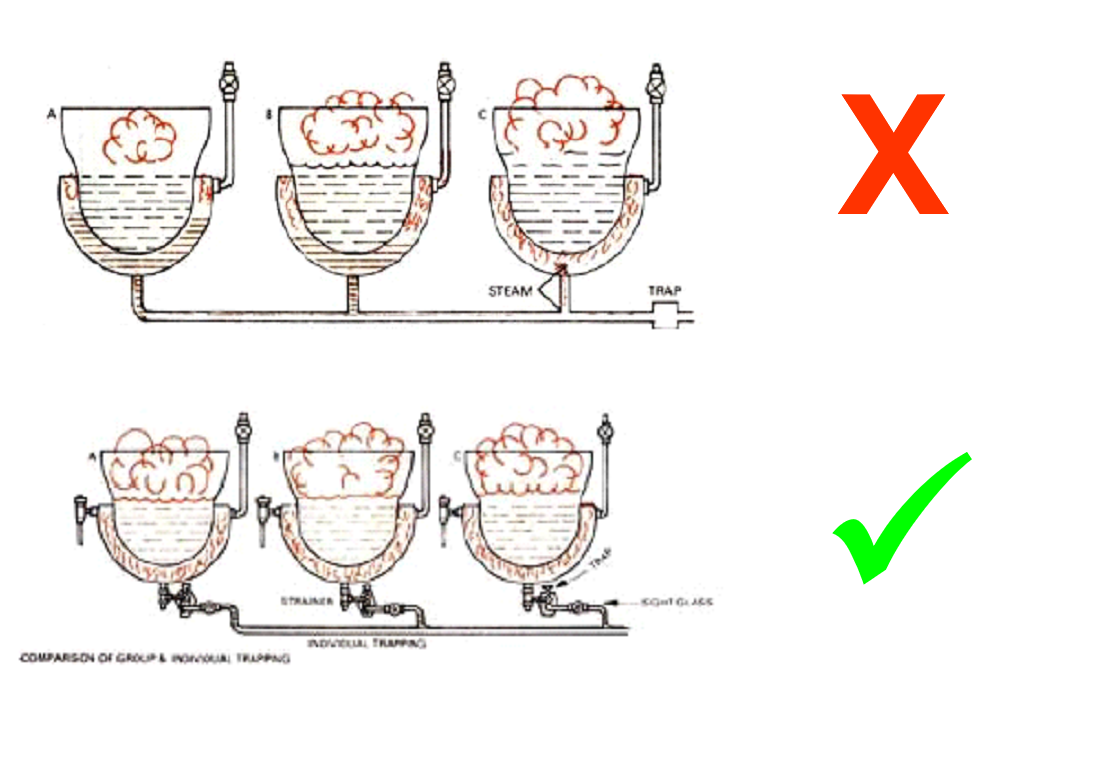

Group trapping

Drain pocket dimensions