Steam distribution system Components

- Strainers

- Purpose

- Stop scale, dirt and other solids

- Protect equipment

- Reduce downtime and maintenance

- Fitted upstream of steam trap, flow meter, control valve

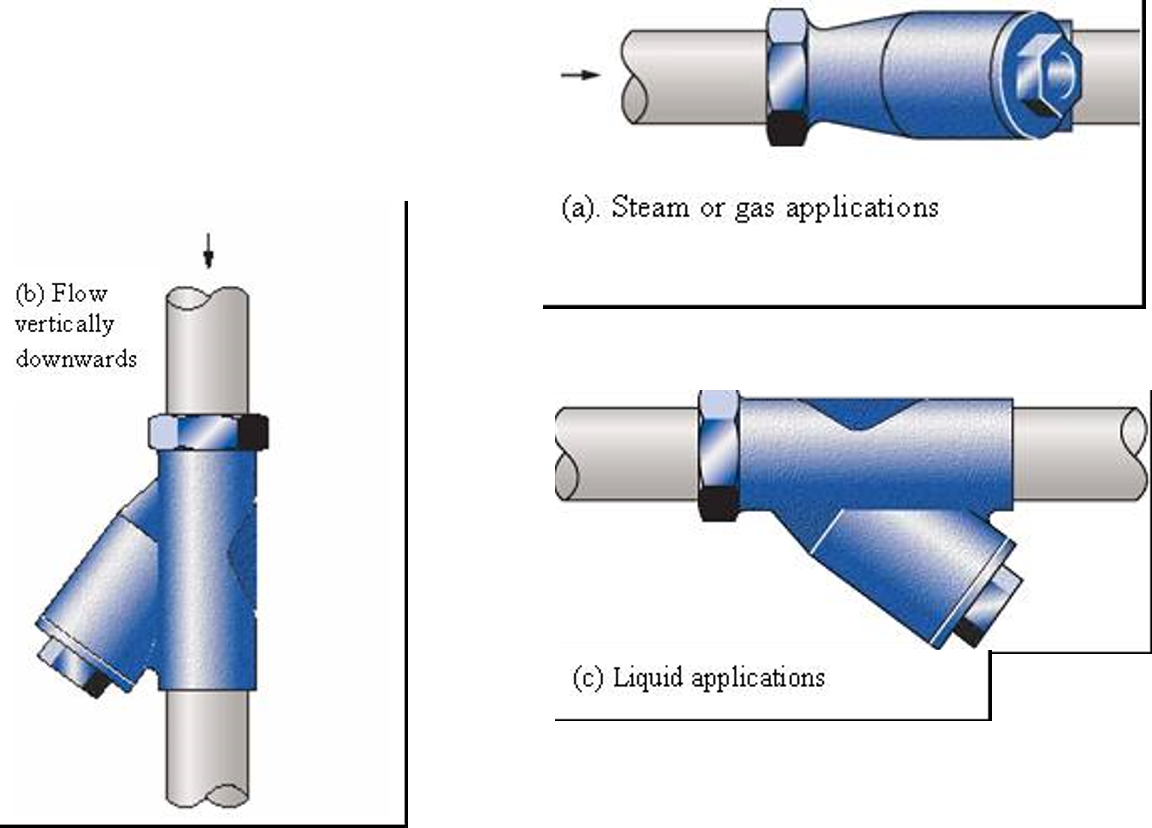

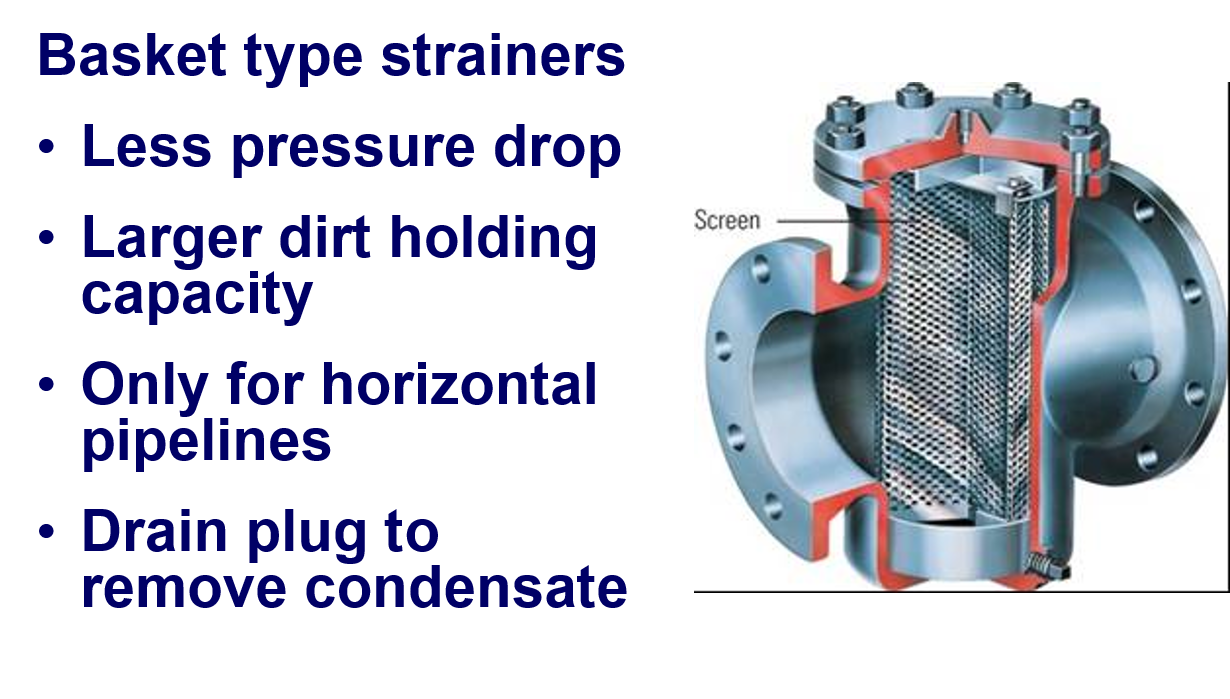

- Two types: Y-type and basket type

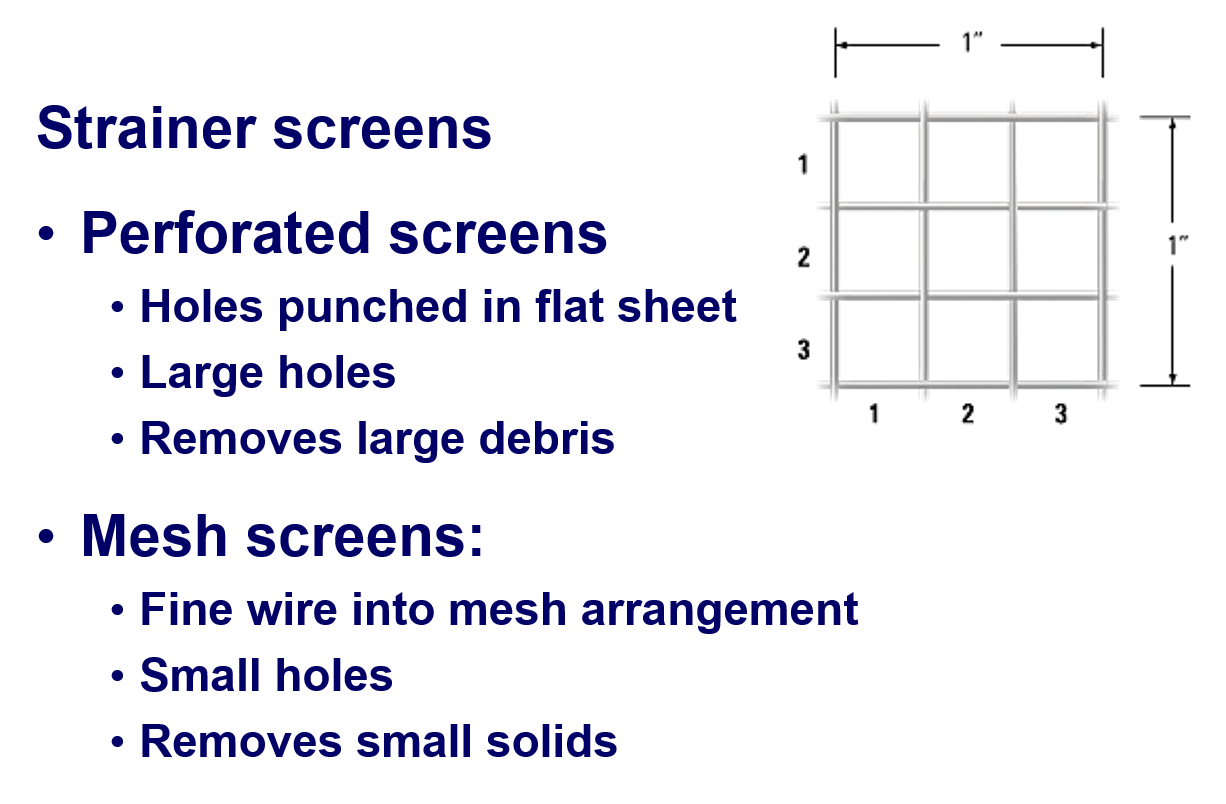

- Other strainer options

- Magnetic inserts: remove iron/steel debris

- Self cleaning strainers

- Mechanical: scraper or brush

- Backwashing: reverse flow direction

- Temporary strainers: equipment protection during start-ups

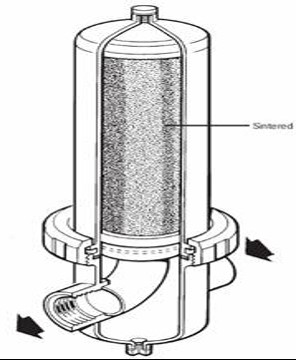

- Filters

- Consists of sintered stainless steel filter element

- Remove smallest particles

- Direct steam injection – e.g. food industry

- Dirty stream may cause product rejection – e.g. paper machines

- Minimal particle emission required from steam humidifiers

- Reduction of steam water content

- Choose correct size due to large pressure drop

- Do not exceed flow rate limits

- For steam applications

- Fit separator upstream to remove condensate

- Fit Y-type strainer upstream to remove large particles

- Identify when cleaning needed

- Pressure gauges

- Pressure switch

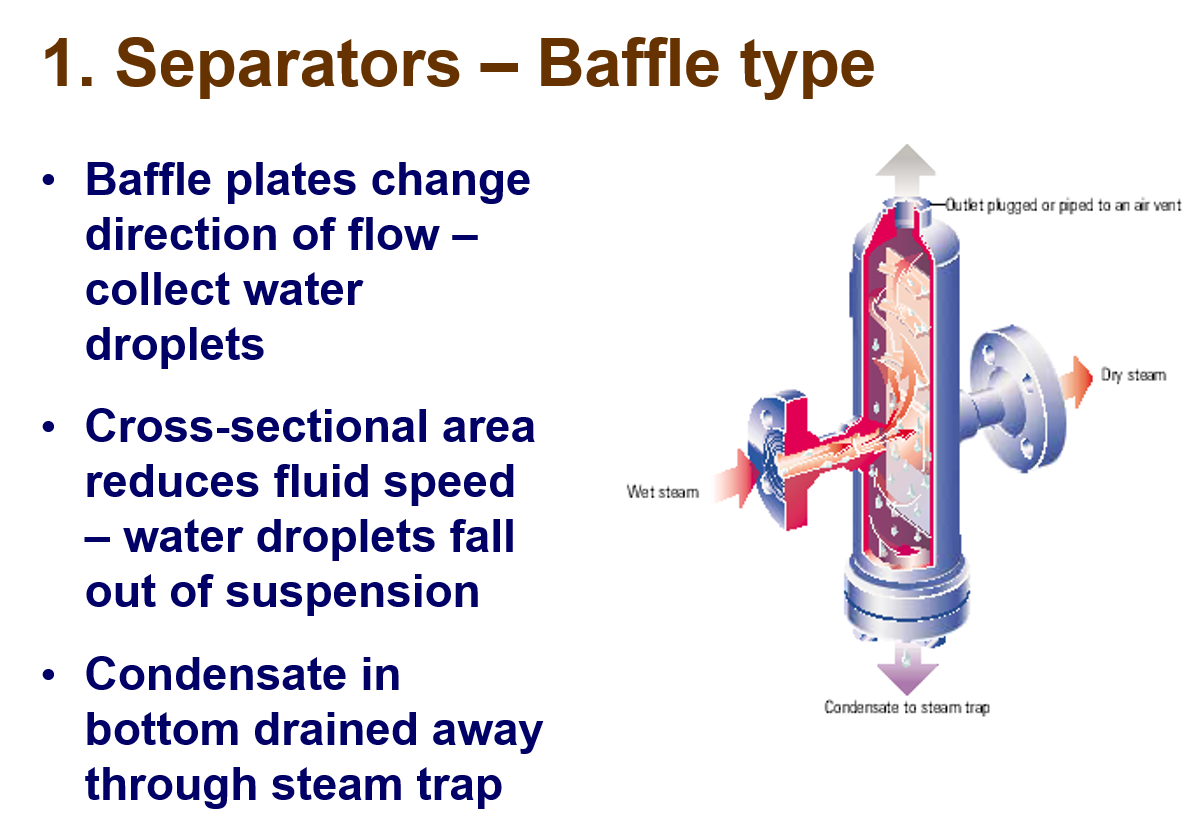

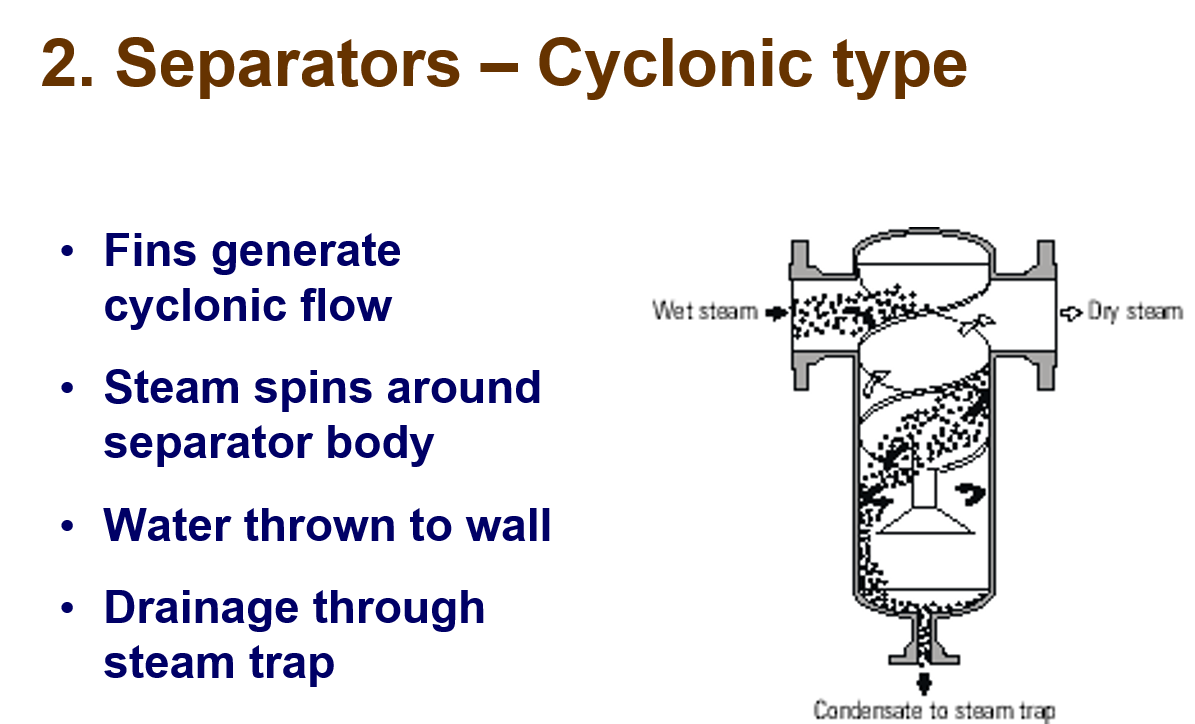

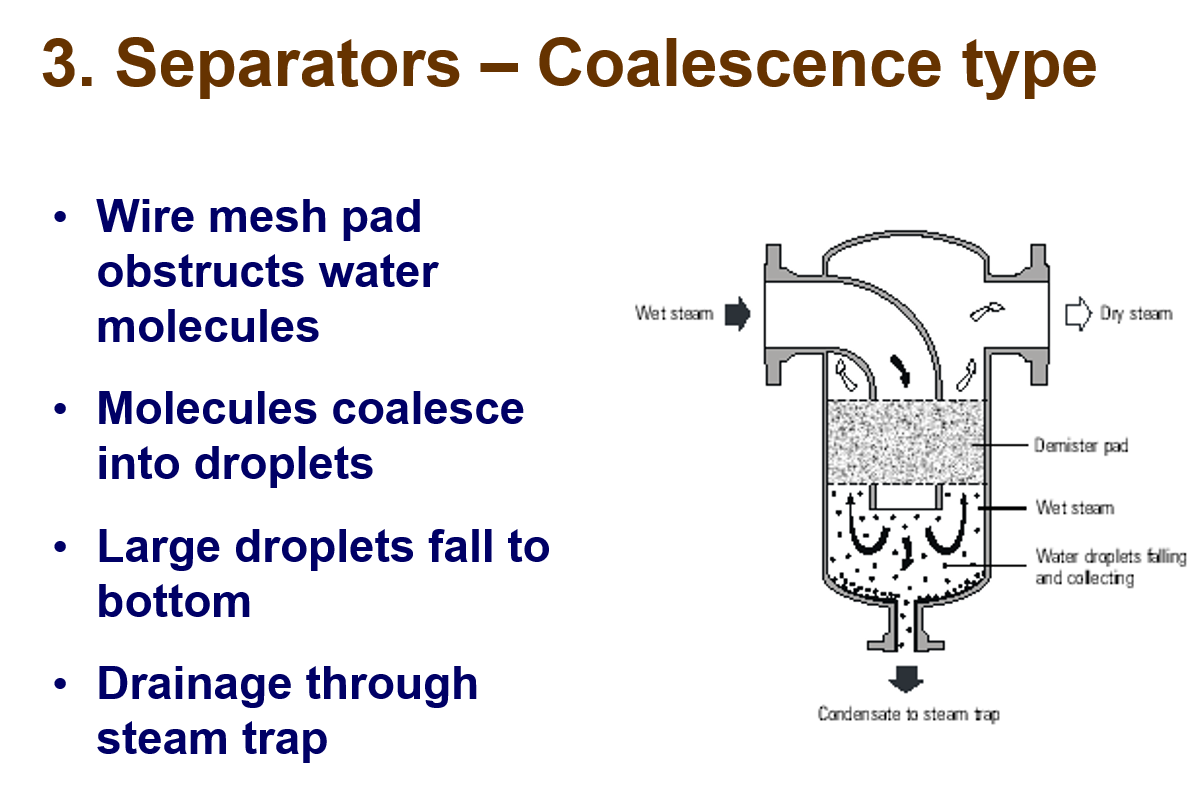

- Separators

- Separators remove suspended water droplets from steam

- Water in steam causes problems

- Water is barrier to heat transfer

- Erosion of valve seals and fittings and corrosion

- Scaling of pipework and heating surfaces from impurities

- Erratic operation and failure of valves and flow meters

- Three types of separators