GOVERNING OF STEAM TURBINE

1.) Mechanism of Governing System

1. Speed Governing Mechanism (Speed Governor)

2. Operational Mechanism

3. Protection Mechanism

4 Regulatory Mechanism

1. Speed Governing Mechanism (Speed Governor)

1.1) Why Governing is required ?

1.2) Characteristics of Governing System (Droop or Regulation or Steady State Regulation of Governing System)

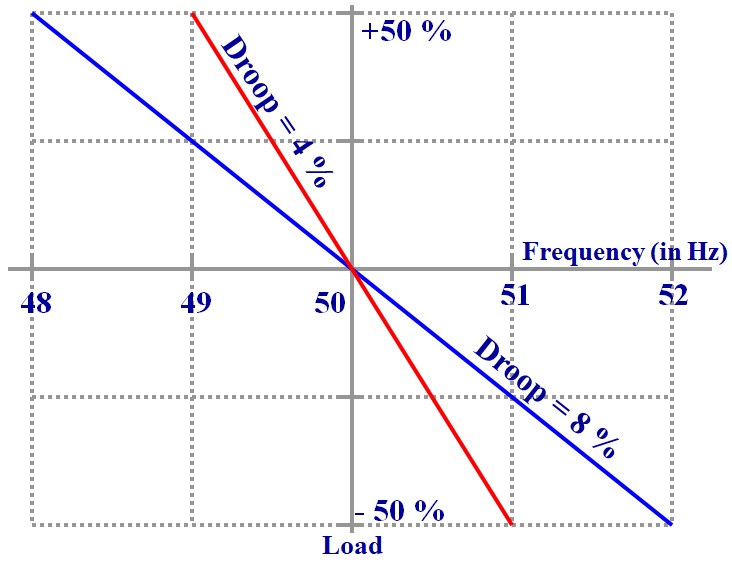

Droop of Governing System / Steady State Regulation/ Droop / Regulation:-

- Steady State regulation/Droop is a measurement of the quickness of response with which the governing system controls the changes in speed .

- This droop percentage at the machine decides the load sharing by the machine connected in the network during demand changes.

- It varies from 2.5% to 8%

- Turbine having less regulation will be more sensitive in the grid and hence will share more load and vice versa

- Normally base load plant has high regulation and Peak load plant has small regulation.

- Droop percentage for Hydro and Gas Turbines are kept usually 3-4% where as for Steam Turbines is kept usually 5-8 %. It insures desired percentage of load distribution between sets running in parallel to maintain the quality of out put i.e. frequency.

Regulation % of Turbine is defined as (No load Speed – Full Load speed) X 100

( Nominal Speed)

The main characteristics of a governing system is therefore the relationship between the generated load of the machine and its speed which is the prime governor input. This is known as the speed-loop droop or frequency regulation characteristics of the governor.

Considering

NR: Rated speed,

NPR : Speed at full load

NO: Speed at No load

The steady state overall frequency regulation is defined as

(II) FREQUENCY VS LOAD CURVE

(III) CHARACTERISTICS OF FREQUENCY INFLUENCE

(IV) Free Governor Mode FGMO

- If speed governor of the governing system of a utility turbine is free to perform corrective action as per its droop characteristics in response to the fluctuation in frequency then this is known as FGMO (Free Governor Mode operation) of governing system.

- If the turbine is on Free governor mode (FGMO) then machine will be proportionately loaded or unloaded by the speed governor accordingly.

(V) Suppression of Free Governor Mode FGMO

- On the other side if the function of speed governor of the governing system is suppressed by any means then it is known as suppression of free governor mode of operation.

- FGMO can be suppressed by using different facilities available with governing system.

- In Suppression of Free Governor Mode, Operation function of governing system of is only

- To start and synchronize TG set

- To change load.

- To provide protection to the turbine.

(VI) THE EFFECT OF REGULATION

(VII) THE EFFE CT OF CHANGING SPEED SET POINT

(VIII) USE OF VARIABLE DROOP SETTINGS FOR CLOSED LOOP LOAD CONTROL

(IX) EFFECT OF DROOP SETTING ON GRID REQUENCY

(X) Governing Of Large Reheat Machines

1.3) Governing/Regulation System PROCESS

1.4) Governing/Regulation System ELEMENTS

- Speed governor

- Follow pilot

- Summation pilot

- Intermediate pilot

- Control valve servomotor

- Load/speed control pilot valve

- Load limiter

- Differentiator

- Electro-hydraulic transducer

- Speeder gear

- ISPUG(in 210 MW only)