Boiler Metallurgy

Requirements of Materials

The following major properties of materials is of interest in the choice of materials for Boiler and Pressure Vessel applications:

- Strength at room temperature and elevated/ service temperature

- Corrosion/ Oxidation resistance

- Stability of structure over a service period normally about 30 years

- Ease of fabrication including welding

Effect of Common Alloying Elements

Carbon: This is the main element which provides strength. For considerations of weldability the carbon content is restricted to 0.25% in IBR and in many of the European codes.

American Code (ASME B&PV) allows carbon up to 0.35%.

The purchase specifications of BHEL restricts the carbon to a maximum value of 0.30%.

Carbon has a major bearing on the high temperature strength also, for example a minimum of 0.04% of carbon is required as per ASME B&PV code to ensure the high temperature creep properties of austenitic SS grades.

Chromium: This is the major alloying element conferring the oxidation /corrosion resistance to the steel. This element also provides resistance to corrosion in sulphur rich flue gases.

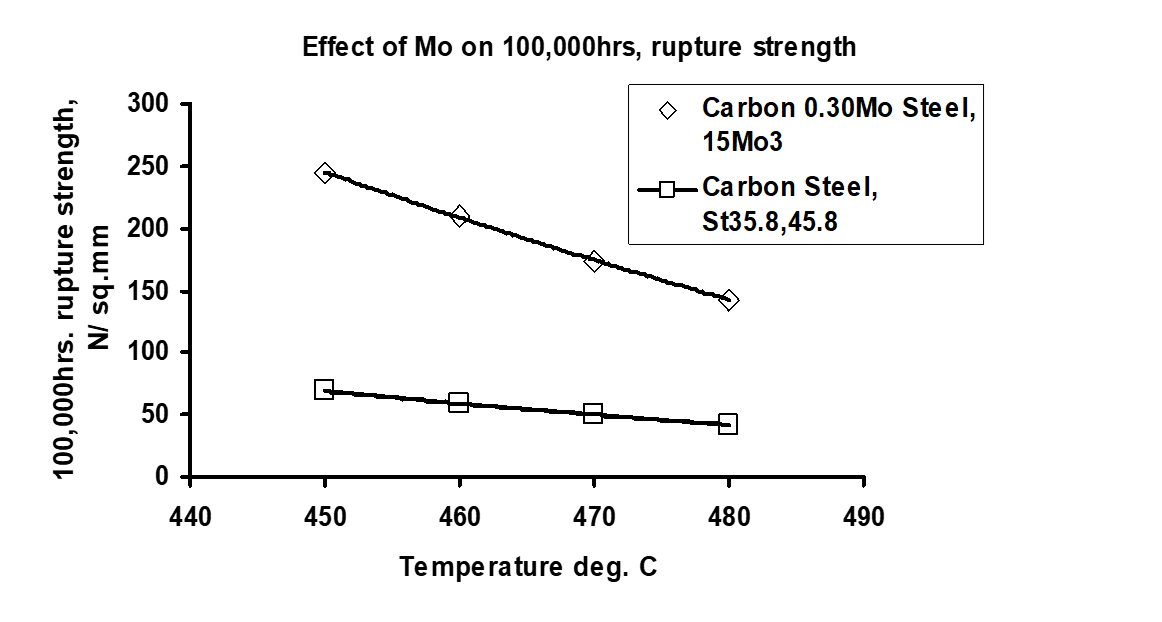

Molybdenum: The main alloy element which confers creep resistance for the steel. 100,000 hrs rupture strength is used in these presentations for the purpose of various comparisons.

Material Selection

- Materials for Main Feed Water Piping : SA 106- C (Carbon Steel)

- Material for Economizer Tubing : SA 210- C (Carbon Steel)

- Material for Water wall Tubing : SA 213- T 22 (2.25 Cr–1.0 Mo)

- Materials for Super heater and Re-heater Tubing : SA 213- T 91 (9Cr-Mo-V)

- Materials for Super heater and Re-heater Steam Piping : SA 335- P 91 (9Cr-1Mo-V)