Differential Expansion of Steam Turbine

1.) Differential Expansion of Steam Turbine:-

- It is the difference between the rotor expansion and the Casing Expansion.

- It is +ve if rotor expands more than casing.

- It is -ve if casing expands more than rotor.

- During initial startup diff Exp. is +ve as rotor mass is less and expands at more faster stage than casing. After full load this gap reduces.

- Diff. Expansion pick up is mounted at the farthest point from the anchor point to record the max difference.

- Differential expansion is “+”while heat expansion value of rotor is larger than heat expansion value of stator, on the contrary, it is “-”. While the unit differential expansion of high-medium and low-pressure exceeds limit, security system will send alarm signal.

2.) Alarm and trip values for differential expansion:-

The rotor is fixed position by the work pad

The alarm value:

High Low

HP +6 mm -3 mm

LP +7 mm -6 mm

The stop value :

High Low

HP +6.3 mm -3.2 mm

LP +7.2 mm -6.2 mm

| S.No | DESCRIPTION | Alarm | TRIP |

| 1 | DIFFERENTIAL EXPANSION OF HP CASING | +6.0mm / -3.0mm | +6.3 / -3.2mm |

| 2 | DIFFERENTIAL EXPANSION OF LP CASING | +7.0mm/-6.0mm | +7.2mm/-6.2mm |

3.) Effect if Differential Expansion is larger:-

| The diff expansion is larger | 1) The high-medium pressure diff expansion is larger.

a) Confirm the trend of diff expansion. b) Maintain the unit load, reduce the fluctuation of main steam temperature, and check high-pressure extraction temperature. c) If the positive diff expansion becomes larger, the main steam temperature should be reduced, or reducing the unit load little by little. d) If the negative diff expansion becomes larger, the main steam temperature should be raised, or raising the unit load little by little. Or raise the cylinder temperature by taking other measures. 2) The low-pressure diff expansion is larger. (There is only the limitation of positive diff expansion.) a) Maintain the unit load, reduce the fluctuation of reheat steam temperature, and check the extraction steam temperature of low-pressure cylinder. b) Reduce the reheat steam temperature or reduce the unit load little by little. |

4.) Turbine Outer Casing & Inter layer Casing Pre Warming System :-

HP casing Pre warming system

- Purpose of the HP casing Pre warming system is to raise the HP inner casing temperature when the temperature below 150 deg c during the start-up system.

- Pre warming steam is taken from Auxiliary steam header.

- Pressure limit is 4.0 kg/cm2 to 6.0 kg/cm2.

- Temperature raising of the casing should be 50 deg c /hr.

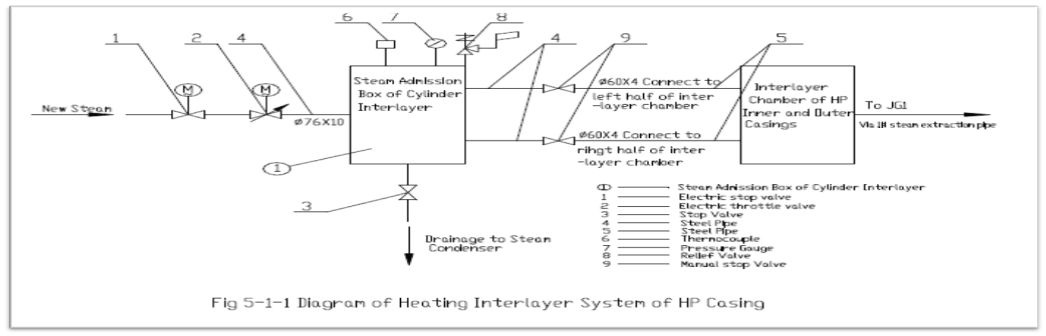

HIP inter layer casing system

- Purpose of the HIP inter layer system is to control the expansion of the HIP inner & outer casings.

- Steam for interlayer heating taken from main steam line.

- Steam pressure limit is 5.0 kg/cm2 to 50.0 kg/cm2.

- Temperature raising of the casing should be 50 deg c /hr.

| Differential temperature limits of TOP & BOTTOM inner casingS | 50 Deg C |

| Differential temperature limits of OUTER & INNER casingS | 50 Deg C |