What Is Fluidization

Topic 1: What Is Fluidization?

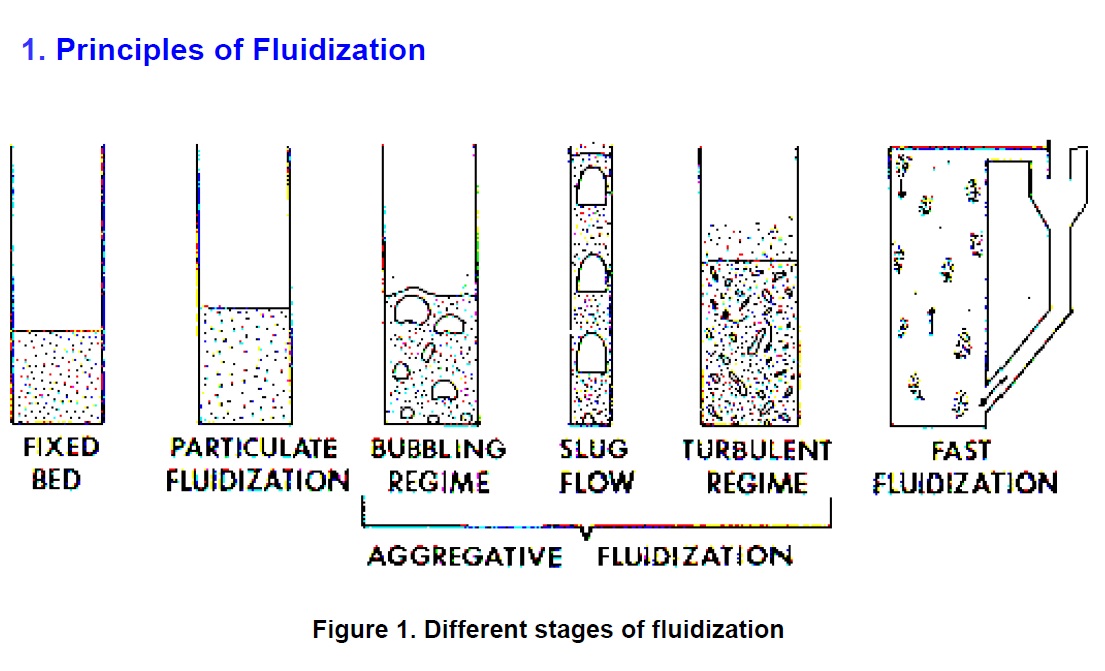

1. Principles of Fluidization

– Incipient fluidization

– Bubbling bed

– Slugging flow

– Turbulent regime

– Fast fluidization

2. Classification of Particles

1.1 Incipient Fluidization

1.1 Incipient Fluidization

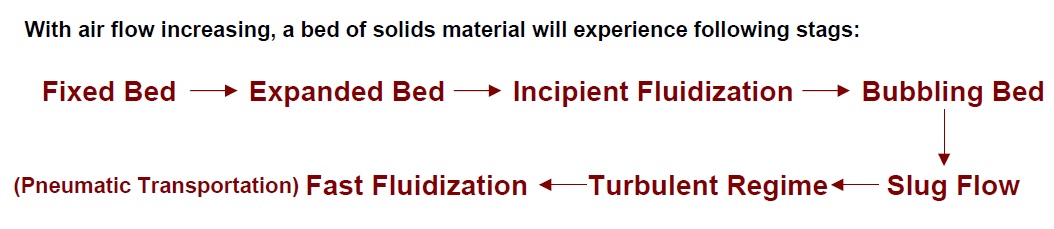

Fluidization is a process in which a bed of particles is converted to a fluid state by means of an upward flow of gas (or liquid);

When a fixed bed of particles is exposed to upward gas-flow, individual particles gradually tend to move apart and bed expansion becomes

noticeable (expanded bed). Pressure drop increases with rising gas flow;

At high airflow rates, a point is reached at which pressure drop becomes equal to bed weight, which enters into a state of incipient fluidization.

1.2 Bubbling Bed

Any additional airflow causes (inherently unstable) rising bubbles in bed

• The bubbles originate at distributor, detach from it, rise and inflate, merge or split, and eventually reach the surface of the bed.

• Distributor is a device that supports the bed & distributes airflow into the bed

Rising bubbles brings about a steady circulation of bed material

• push aside particles and aspire them in their wake;

• result in a thorough and steady mixing of bed materials;

• At sufficiently high bubbling rates, floating light or settling dense material are spread homogeneously throughout the bed.

A high rate of heat transfer in the bed is achieved

• The bed temperature tends to be strictly homogeneous in any case.

A high mass exchange between gas and fuel particles is also achieved

Probably, gas short-circuiting sometimes occurs to a certain extent

A bubbling bed resembles a boiling liquid, such as:

• The horizontal boundary between the fluidized bed and air phase above it;

• Fluid-like features of the bed, which can flow out of a hole or over a weir;

• The principle of communicating fluidized vessels;

• Light materials to float and dense materials to sink to achieve separation;

• The hydrostatic pressure, which rises with the depth in the bed;

• The steady but erratic movement of individual particles

1.3 Slugging Flow

FB is operated using a gas velocity well above incipient fluidization

• In fluidized state, pressure drop no longer increases significantly with gas flow.

When gas flow further increases, slugging may occur.

• slugging is a situation, occurring frequently in narrow slender beds;

• bubbles grow in size and coalesce so that they cover entire bed cross section;

• the slugs push bed material upwards until it rains through them, temporarily breaking up the slug;

• slugging regime is undesirable, because it is accompanied by erratic pressure shocks and a rather poor gas/particle contact

1.4 Turbulent Regime

When gas flow increases further, the bed is termed turbulent in a riser

1.5 Fast Fluidization

When gas flow increases even further, the bed is termed fast

CFB operates at velocities, corresponding to pneumatic transportation

2. Classification of Particles

Geldart’s classification

– Homogeneously fluidizable powders;

– Powders fluidizable with a bubbling regime, e.g. sand;

– Cohesive powders, difficult to fluidize, e.g. cement and fly-ash;

– Pellets, fluids;

– Others able with a bubbling regime, e.g. plastic pellets, corn.