What Is CFB Technology

Contents:-

1. History

2. General Advantages

3. CFB System

– Furnace

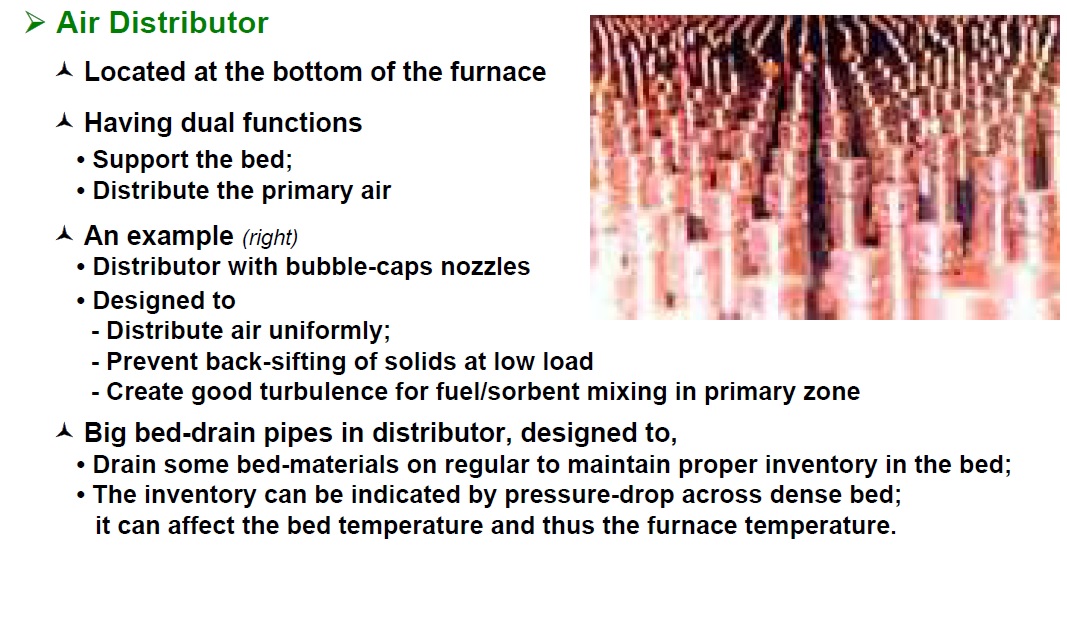

– Air Distributor

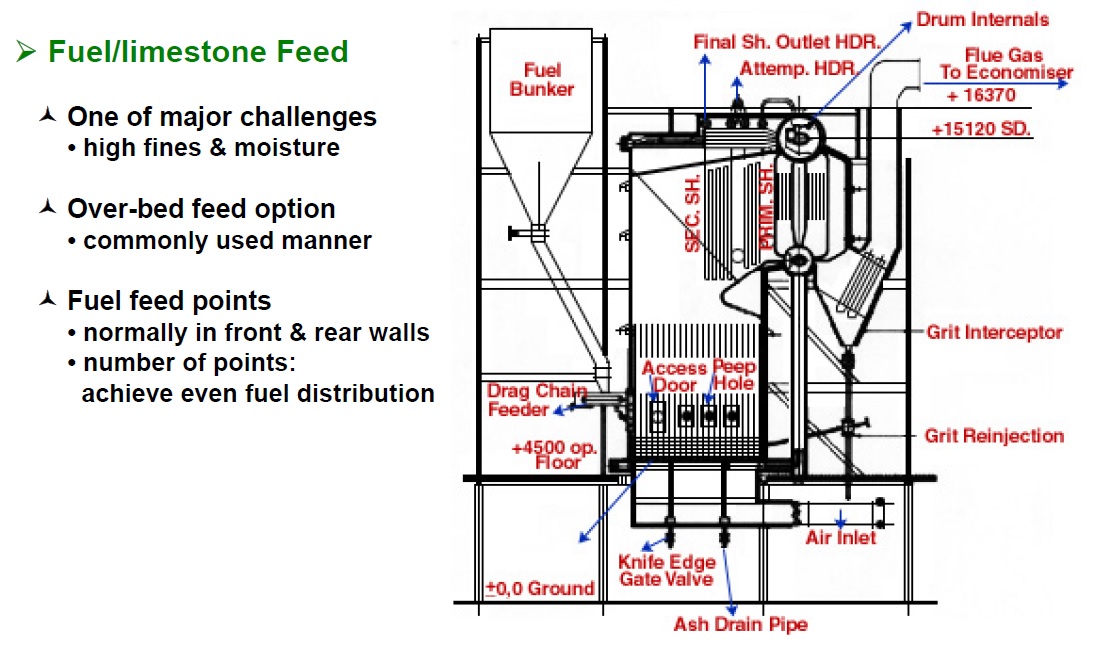

– Fuel/limestone feed

– Solids recycle device

– External heat exchanger (EHE)

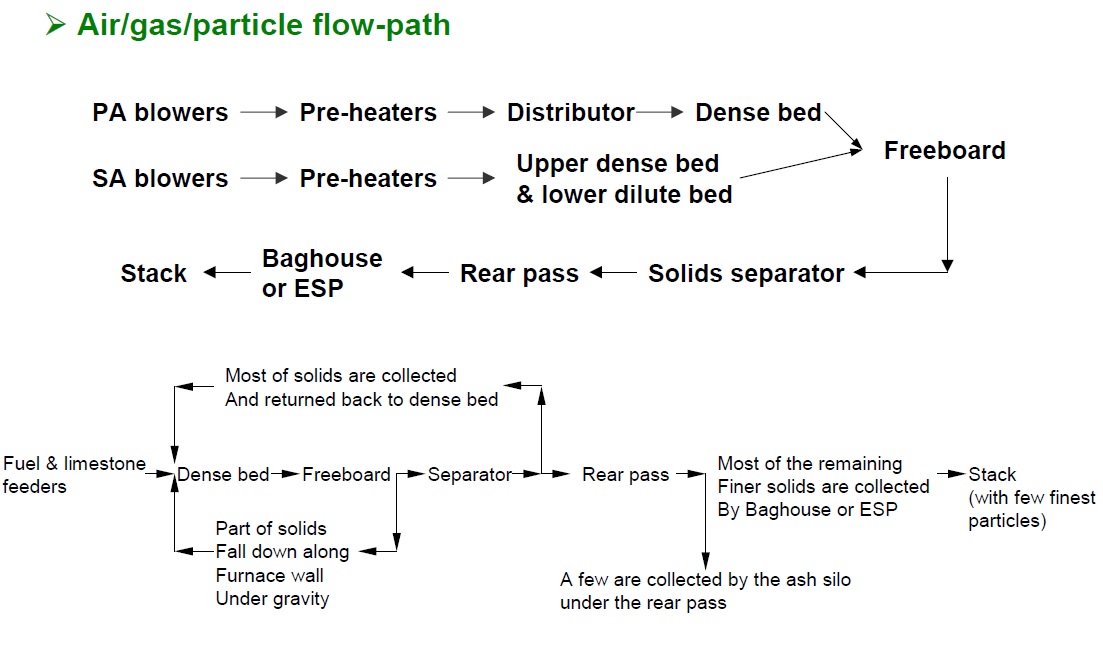

– Air/gas/particle flow-path

1. History

- less than 20 years old

- Modern and mature technology to burn coal and other solid fuels

- More than 400 CFB boilers in operation worldwide

- Unit capacity: from 5MW to 250MW (electricity)

- General description:

• Use fluidized bed principle;

• Crushed (6~12 mm) fuel and limestone are injected into the lower furnace. The particles are suspended in a stream of upwardly flowing air that enters the bottom of the furnace through air distribution nozzles;

• Balance of combustion air is admitted above the bottom of the furnace as secondary air;

• Combustion takes place at 815~925°C, with uniform combustion condition in chamber;

• Fine particle (< 450 microns) are elutriated upward in furnace with flue gas of 4~6 m/s.

Particles are then collected by the solids separators and circulated back into the furnace.

Individual particles may recycle anything from 10 to 50 times

• Particles’ circulation provides efficient heat transfer to furnace walls and longer residence

time for carbon and limestone utilization.

2. General Advantages

Fuel Flexibility

The relatively low furnace temperatures (815~925°C) are below ash softening temperature of nearly all fuels;

Therefore, furnace design is independent of ash characteristics

Low SO2 Emissions

Limestone is an effective sulfur sorbent in temperature range of 815~925 °C

SO2 removal efficiency: >95%

Low NOx Emissions

Very low NOx emission, thanks to

– Low furnace temperature

– Air staging to the furnace

High combustion efficiency (even for difficult-to-burn fuels)

Very long solids residence time in furnace due to re-circulation

Vigorous solids/gas mixing in furnace

These two compensate negative effect of low furnace temperature

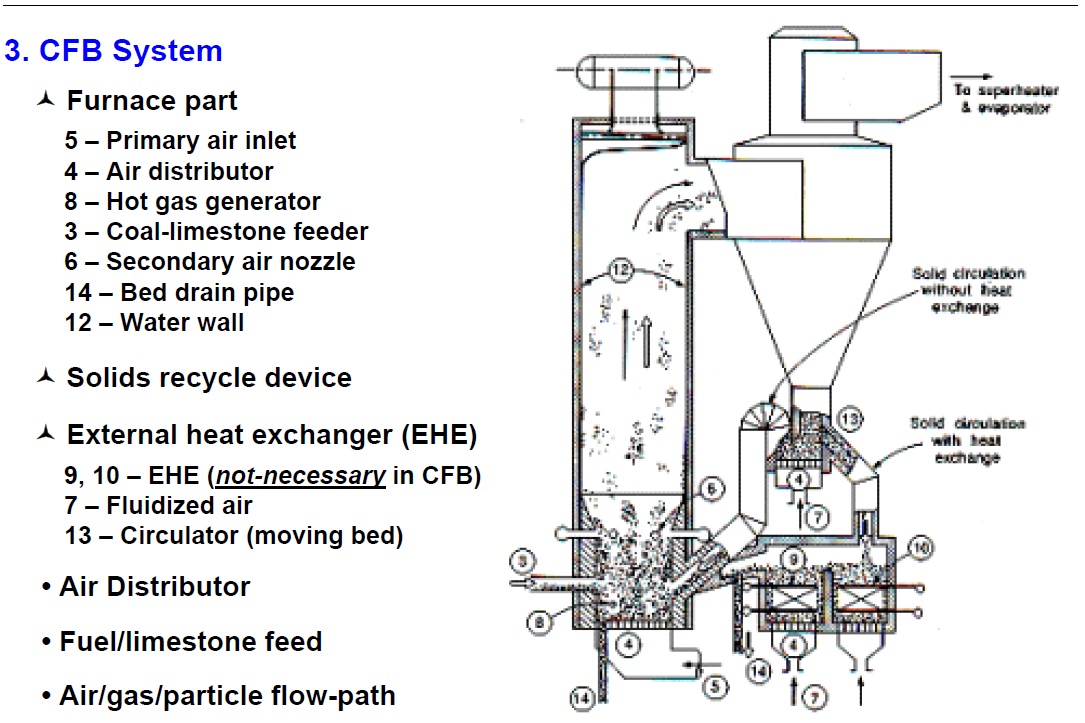

3. CFB System

3.1 Furnace

Operating at velocities corresponding to pneumatic transportation regime

• CFB furnace is high, in order to allow for a long residence time of the gas;

• Furnace cross-section is selected based on flue gas superficial velocity.

Furnace enclosure is made of gas-tight membrane water-cooled walls

Refractory to protect against corrosion & erosion

• Thin layer of refractory on all lower furnace walls;

• In dense bed, an ultra high strength abrasion-resistant low cement alumina refractory of 16~25 mm thick is applied over a dense pin studded pattern.

Furnace temperature is precisely controlled by maintaining proper inventory

Combustion Air

• Primary air: through distributor into furnace bottom, typically 60~70% of total air

• Secondary air: introduced through over fire nozzles & material injection points into the top of lower dense bed, 30~40% of total air. Several levels.

• Primary zone: the region below the lower secondary air level.

– The primary zone has reduced cross section to provide good mixing and promote solids entrainment at low load;

– Startup burners, fuel fed points & secondary ash recycle points located.

Dense bed vs. Dilute bed (freeboard region)

• Dense bed: In the primary zone [~4.25 m/s];

– Design for uniform distribution & intensive mixing of PA & bed solids

– High mass-transfer rate provides intense combustion & sulfation;

– High heat capacity of the bed allows burning any kind of fuels;

– Sub-stoichiometric conditions there limit NOx formation;

– Special erosion-protection ways needed.

• Dilute bed: In the middle and upper furnace [~6 m/s], design for

– Used as a disengagement zone: most of material carried-over from bed can settle and return to the bed inside furnace

– Served as a post-combustion chamber: sufficient residence time for fuel burnout and sulfur capture

– Height required to burnout volatiles and to settle entrained particles

The former is often larger than the latter; so most of the entrained solids in freeboard region re-circulate within furnace

– High solid inventory for better heat transfer rates & sorbent reaction

Solids densities are relatively high (level of 10 kg/m3 gas): very good

for gas-solid reactions and for heat transfer

– Heat transfer surface of the enclosure walls

– Good mixing of secondary air and combustion products

• Transition between them is gradual.