Turbine Vacuum system

- What Is vacuum?

- Why Vacuum system is required ?

- Parts of Vacuum system

- Steam Ejectors

- Vacuum Pumps

What is Vacuum ?

Pressure Below Atmospheric is known as Vacuum.

Value is = 760 mmHg or 10.332 mmWC

= 1.013 bar

= 1.033 Kg/cm2(All Values are at See Level)

It changes with Temperature & Height above See level.

It Decreases with Increase in Temp. & Height.

At our Site level it is 0.965 Kg/cm2 or 710 mmHg.

Why is it required?

- The steam turbine itself is a device to convert the heat in steam to mechanical power.

- Enthalpy drop across the turbine decides the work output of the turbine. For increasing this enthalpy drop across the turbine we need effective condenser vacuum system.

- By condensing the exhaust steam of turbine, the exhaust pressure is brought down below atmospheric pressure, increasing the steam pressure drop between inlet and exhaust of steam turbine. This further reduction in exhaust pressure gives out more heat per unit weight of steam input to the steam turbine, for conversion to mechanical power.

Why we need Vacuum in Condenser?

Parts of Vacuum System

- ACC

- Ejectors/Vacuum pumps

- Gland Sealing System

STEAM EJECTORS

- Multistage condensing ejector systems can be designed to operate at any condenser pressure and designs are not limited by the available cooling water temperature to the intercondenser (condensate cooled systems are common).

- These systems have no moving parts, are the most reliable, require the least maintenance of all venting systems, and are the least expensive in initial cost.

- Once equipment is built for a given motive steam pressure that pressure must be maintained or the ejector will become unstable and lose vacuum.

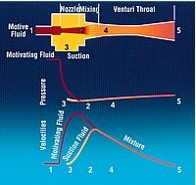

Both Hogger and Ejector works on Convergent-Divergent Diffuser Property.

- MAIN AIR EJECTOR

- STARTING AIR EJECTORS

VACUUM PUMPS

- The liquid-ring vacuum pump is a specific form of rotary positive-displacement pump utilizing liquid as the principal element in gas compression.

- The working parts of the liquid ring vacuum pump consist of a multi-bladed impeller mounted eccentrically in a round casing which is partly filled with liquid. As the impeller rotates, the liquid is thrown by centrifugal force to form a liquid ring which is concentric with the periphery of the casing.

- In addition to being the compressing medium, the liquid ring absorbs the heat generated by compression and friction, absorbs any liquid slugs or vapor entering with the gas stream, and condenses water vapor entering with the gas.

- A closed loop (or total recirculation) seal system is commonly used. The seal water temperature warmer than the cooling water to the pump heat exchanger, which is normally taken from the same source as the condenser cooling water (CW or ARCW).

- The vacuum attainable by a liquid ring vacuum pump is limited by the vapor pressure of the seal fluid.

- As the operating vacuum approaches the vapor pressure of the seal, more and more of the seal fluid will “flash” into vapor.

- The capacity of the liquid ring vacuum pump is reduced as more of the impeller space is occupied by vapor from the seal fluid, leaving less space available to accept the incoming load.

- If allowed to continue, cavitation will occur inside the pump, resulting in damage to internal surfaces, and preventing the pump from achieving greater vacuum levels.