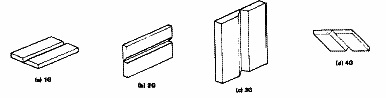

Test positions for fillet & groove welding

Training, Seminar & Technology For Engineers

To become a Part of Training of Industrial Employees

Training, Seminar & Technology For Engineers

To become a Part of Training of Industrial Employees

Test positions for fillet & groove welding