Steam Turbine Erection Sequence

1.) ERECTION SEQUENCE

(For 500 MW Fixed pedestal type Turbine with spring loaded foundation)

- Cleaning and checking of Turbine and Generator foundations as per the transverse and longitudinal axis including their elevation.

- Prepare and install LP base plates, HP front pedestal, HP rear pedestal, LP front pedestal, LP rear pedestal along with their anchor bolts and anchor plates.

- Provisionally align and level all the pedestal and LP base plates as per the transverse and longitudinal axis including their elevation.

- Matching of anchor plates of pedestal and LP base plates to ensure their perfect seating.

- Finally align and level HP front, HP rear, LP front and LP rear pedestals along with LP base plates as per the transverse and longitudinal axis including their elevation and catenary as per the design.

- Prepare and install steel bars for LP casing centralising keys in foundation slab as per the required center line .

- Weld locating ring of LP front pedestal and steel bars of LP front and LP rear centralising keys.

- Prepare shuttering and grouting of the pedestals and LP base plates including anchor plates of HP rear pedestal.

- Prepare, install, align/ level both the LP girder along with their carrier plates.

- Prepare , install and assemble LP front and rear end walls with the LP girders.

- Level / align LP outer casing lower half as per the transverse and longitudinal axis of the machine.

- Install permanent packers of LP outer casing including their radial and axial keys.

- Prepare and install LP inner outer casing along with gusset plates in position

- Align LP inner outer casing lower half and level it. Install LP casing parting plane platform .

- Prepare and install LP front and LP rear lower half shaft seals housing and align it provisionally.

- Prepare and install LP rotor along with their bellows in position.

- Align LP rotor radially and axially in position and record free run out of rotor.

- Record/ Ensure radial and axial clearances of the LP casing including rotor float including fitting of final axial keys of the LP inner casing .

- Box up LP inner inner casing and heat tighten the parting plane bolts.

- Box up LP inner outer casing .

- Prepare and place HP module in position on temporary

- Transfer the load of HP rotor on bearings from the transport device and align it radially and axially.

- Check free run out of HP rotor on journal and coupling face including its float.

- Prepare and place IP module in position on temporary (In case IP module is sent to site in disassembled condition, refer Instruction T1-08-0606G.

- Loading of IP rear end of the shaft on bearing and removal of transport device.

- Provisionally align HP , IP and LP rotor .

- Couple HP / IP rotor on temporary Bolts and align rotor / casing radially and axially.

- Record/ Ensure IP rotor float by shifting HP casing axially.

- Conduct Horn drop test of HP casing without any radial and axial keys and pipe lines.

- Conduct Horn drop test of IP casing without IP inlet upper half pipe lines.

- Assembly of breech nut of HP casing and Main Steam Stop & Control valve assembly.

- Erection of Reheat Stop & Control valve assembly.

- Weld IP inlet upper half pipe and record Horn drop values without radial-axial keys.

- Alignment of HP/IP/LP rotors and their coupling on temporary bolts including its couple runout.

- Swing check of HP rotor on its front end with temporary alternate bolt tightened on HP/IP coupling.

- MOP alignment and its doweling.

- Reaming/honing of HP/IP and LP/IP coupling including fitting of final coupling bolts.

- Fixing of axial position of shaft and assembly of thrust bearing including its colour matching.

- Roll check of HP/IP casing and fixing of radial and axial keys of the casing (Casing final packers need not to be put at this stage).

- Assembly of bearings and checking of all clearances including fittings of side pads of bearing, yoke keys etc.

- Turbovisory works in all the pedestal i.e. assembly and calibration of thrust bearing axial shift, LP rotor expansions pick up, Hall generator and thermocouples of bearing .

- Preparations of the bearing for oil flushing.

- Oil flushing of the machine and normalizing the bearing after oil flushing.

- Preparation and floating of TG deck as per Instruction No. T1-08-0909G.

- Decoupling of HP / IP, LP/IP, LP/Gen., Gen./Exciter coupling and rechecking of alignment/catenary after floating of TG deck spring.

- Final tightening of HP/IP, IP/LP , LP/Generator and Generator / Exciter coupling after correcting the alignment including their couple run out and swing check of rotor on HP Front and exciter

- Checking /Correction of LP shaft seal clearance after floating of TG deck with CW pump in operation and water in the hot well of condenser upto operating level.

- Roll check of HP, IP casing in up and down direction only with TG deck in floating condition and CW pump in operation including water in hot well upto normal level.

- Assembly of final packers of the HP, IP casing after completing the roll check in up and down direction.

- Recording of final Horn drop of HP and IP casing after completing the welding of HP inlet, HP exhaust , IP inlet and Cross around piping.

- Preparation and boxing up of LP casing after competing the full Roll check of LP casing and fitting of final casing packers and radial keys.

- Barring gear.

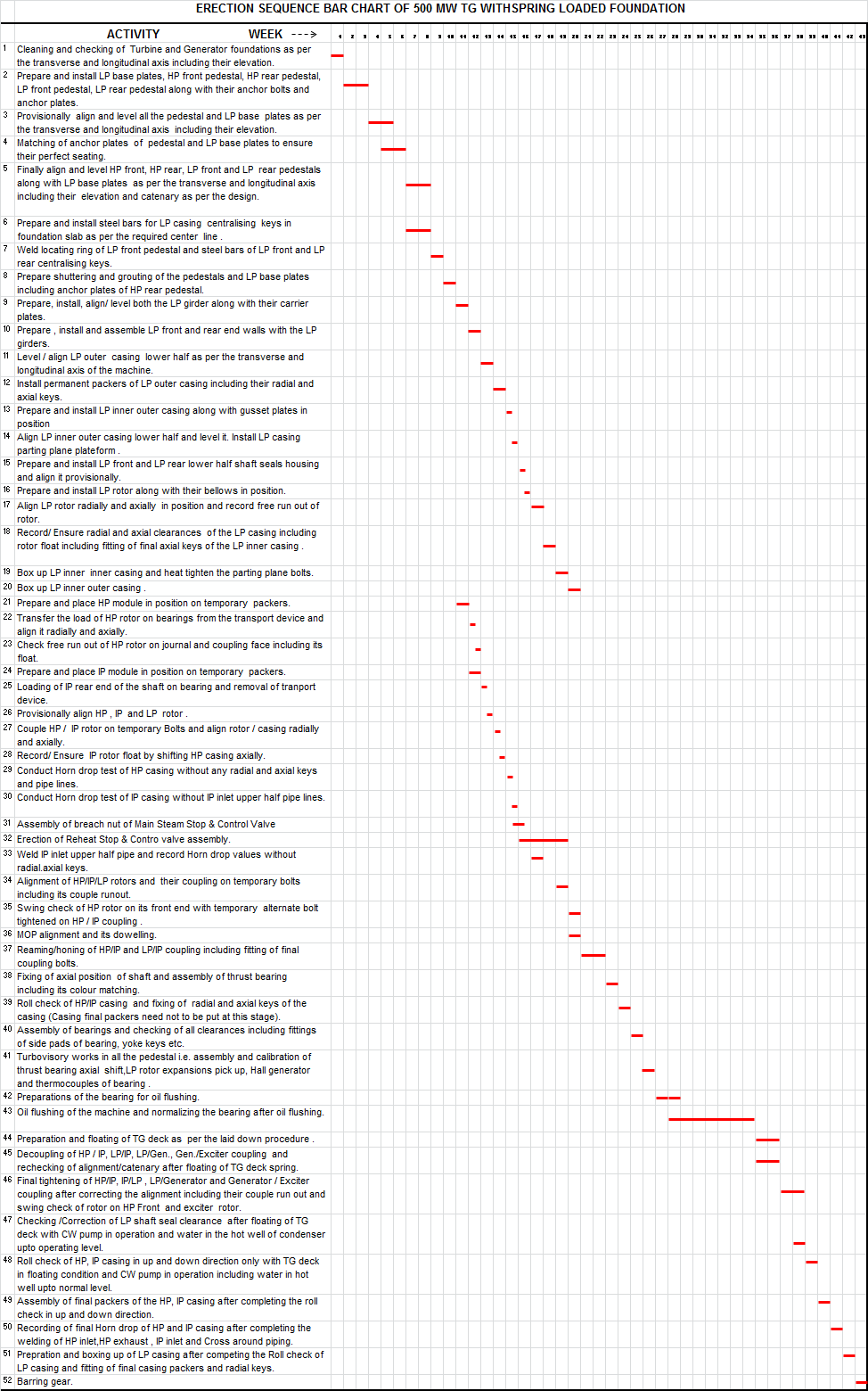

2.) ERECTION SEQUENCE BAR CHART:-

3.) ERECTION PROCEDURE STEP BY STEP:-

1. CHECKING OF FOUNDATION BEFORE CASTING

1.1. Customer to provide, center line and elevation point.

1.2. Check positioning of all the inserts and fixed points with respect to center line in transverse and longitudinal direction as per BHEL Hardwar drawings.

1.3. Check elevation of all points.

1.4. Check verticality of all the pipe sleeves with the help of plumb.

1.5. Ensure proper locking of all the insert and fixed points before grouting.

1.6. Ensure leveling on the fixed points of LP girder and LP rear pedestal.

1.7. Preserve machined surfaces of all the fixed points against any damages due to Improper handling.

1.8. Ensure proper flatness of the bottom seating plate of all the inserts.

1.9. Ensure proper stiffeners in all the vertical and horizontal embedment provided for various purposes like hangers and supports etc.

1.10. Ensure proper cleaning of the area before casting.

1.11. Remove all unwanted material.

NOTE: In case of spring loaded TG deck refer Installation Instruction prior to positioning of inserts etc.

2. CHECKS DURING CASTING/POURING OF CONCRETE

2.1. Casting of foundation\TG deck should be carried out immediately after inspection of the foundation\TG deck i.e. within 3-4 days after final inspection to avoid any disturbance to the inserts and fixed point.

2.2. Ensure no disturbance to the insert etc. during pouring of concrete while vibrators are used.

2.3. About 15-20 mm extra concrete may be left on top on all the pedestals and LP base plate area for chipping/cleaning purpose at a later date.

2.4. Close all the pipe sleeve from top to avoid entry of concrete inside. Alternately the pipe sleeve should be filled with sand.

3. CHECKING OF FOUNDATION AFTER CASTING

3.1. Clean complete foundation and remove all shuttering etc.

3.2. Ensure there is no loose concrete layer in the region where the pedestal and base plates are to be laid. No repair should be done in this region without consulting the turbine erection engineer.

3.3. Cover all the opening before checking any dimensional measurement to avoid any accident.

3.4. Establish a suitable longitudinal axis considering the fixed point of the LP rear pedestal and various pipe sleeves / inserts.

3.5. Establish a transverse axis as 90 degree with the help of the odolite.

3.6. Measure pitching/elevation of all the inserts and fixed points.

3.7. Measure elevation of all foundation on different pedestal and LP base plate area.

3.8. Check level of LP rear pedestal fixed points and if required correction may be carried out.

4. PREPARATION OF FOUNDATION FOR PLACEMENT OF PEDESTALS AND BASE PLATES:

4.1. Foundation are to be cleaned and loose concrete are to be chipped off.

4.2. Maintain elevation of foundation to ensure correct thickness of non-shrink grout.

4.3. A reference point for elevation in respect of machine center line (equivalent to LP rear pedestal) is to be maintained at a proper place. This point is to be preserved with proper protection. For making reference point a one side ground plate of about 200 x300 x20 mm may be used. This may be welded on a I-beam near Generator. The ground position of the plate is to be kept on top side and all elevation are to be transferred from this point with the help of water level jar. A correct elevation reading is to be punched on this plate. This reference point is to be used only during the turbine erection period.

4.4. Clean and deburr piping sleeves of the foundation on ID/OD of the pipe.

4.5. Ensure all corners of the foundation remains perfect during chipping of extra concrete of foundation.

5. PLACEMENT OF PEDESTALS

5.1. Open and clean the pedestal.

5.2. Ensure there is no paint/oil on bottom face of the pedestal sole plate.

5.3. Ensure there is no paint on inside surface or the pedestal and if required sand blasting may be carried out at site.

5.4. Ensure correct fitting/clearance of locating rings of LP rear pedestal.

5.5. The half bore error of pedestals is punched by manufacturing unit however in case it is not there, measure and punch half bore error of pedestal in left/right side of the pedestal. If the error is nil then this may be punched as zero-zero.

5.6. Ensure that the pedestal parting plane is feeler tight after tightening all the parting plane bolts. If required, colour matching may be carried out but scraping/cutting is to be done on upper half cover only.

5.7. Check proper colour contact of spherical/cylindrical supports of the bearing with the pedestal.

5.8. Check contact between spherical Torus piece of bearing and spherical/cylindrical seat. In case of any variation in contact no scraping/cutting to be carried out at site and this may be referred to manufacturing unit. Also refer T1-08-0808G. Check centering of individual bearing w.r.t. pedestal seal bores by fixing pianowire on individual pedestal.

5.9. Ensure cleanliness of all pedestal oil lines. Close opening of oil lines of pedestal to avoid any foreign material entering in these pipe lines during erection at site.

5.10. Weld MOP suction and discharge pipe lines in HP front pedestal as per the drawing before placement.

5.11. Assemble protection sheet in the foundation bolt holes of pedestals.

5.12. Assemble anchor bolts along with anchor plate of the pedestals. Ensure that there is good contact available to the backing plate with the foundation. If required colour matching/grinding may be carried out to achieve the contact.

5.13. Assemble protection sheet in the anchor bolt hole from bottom side of HP rear pedestal foundation to avoid entry of grout metal.

5.14. Ensure level of both anchor plate of H.P. rear pedestal with 70-90 mm gap for filling of grouting concrete.

5.15. Adjust height of the Anchor Bolts as specified in the drawing.

6. PLACEMENT OF LP BASE PLATE, OVER THE FOUNDATION :

6.1. Clean all the four base plates.

6.2. Mark/punch center line on the base plate as per drawing.

6.3. Ensure proper cleaning of base plate on bottom side.

6.4. Put identification marks on each base plate to avoid any mistake in positioning of the same.

6.5. Do colour matching of all the eight nos. carrier plate on both the faces.

6.6. Match LP base plate with the individual carrier plate.

6.7. Place all the four base plates in position along with their leveling screws and foundation bolts.

6.8. Provisionally align and level all the four base plates.

6.9. Assemble protection sheet in the foundation bolt holes.

7. ALIGNMENT OF PEDESTALS AND LP BASE PLATES

7.1. Provisionally align and level all the four pedestals including LP base plates with reference to the earlier marked longitudinal and transverse axis. The elevation reference is to be taken from the already positioned plate for this purpose.

7.2. Align and level LP rear pedestal and set the elevation as per machine center line.

7.3. Use piano wire arrangement with micrometer for centering of pedestal bore and use water level jar for setting of elevation. Use measuring tape to maintain pitching of the bearing from one pedestal to another. Pedestals are to be set in level condition on both longitudinal and transverse direction. Align and level HP front, HP rear and LP front pedestals. Elevation of the pedestals are to be set as per catenary of the machine considering the half bore error of the pedestal if any.

7.4. Align and level, LP base plates. Elevation of LP base plate is to be kept higher than the rear pair of LP base plate in line with catenary of rotor.

7.5. After alignment of LP rear pedestal weld the locating rings as mentioned in the drawing.

7.6. During welding of locating ring, ensure that there is no movement in the pedestal in any of the direction.

8. GROUTING OF PEDESTALS AND LP BASE PLATES

8.1. Fill 3 to 8 mm washed Pea-gravel in all the anchor bolts sleeves. These gravel are necessary to give damping effect to the anchor bolts during operation of the machine.

8.2. Seal anchor bolts holes after filling of gravel to avoid any entry of grout metal. Medical tape may be used for sealing of these anchor bolt holes.

8.3. Clean foundation with compressed air.

8.4. Make shuttering of all the pedestal and LP base plates. Use thick polythene sheet inside the shuttering to give better finish and avoid moisture absorption by shuttering.

8.5. Shuttering should be made with maximum care to avoid any leakage of grout concrete. All sides of the shuttering are to be sealed either with some sealing compound or with thick mixture of grout material to avoid leakage of grout material.

8.6. Foundation are to be kept wet for about 6 hrs. before grouting.

8.7. Non shrinkage cement duly approved by BHEL is to be used for grouting of the pedestals and base plate.

8.8. Use fresh stock of the grouting material only and check the strength of the material before use.

8.9. During grouting, the mixture has to be poured from one end only and it has to flow to opposite end to avoid any blockage of air pocket.

8.10. Water curing is to be carried out for about 10 days duration.

8.11. All anchor bolts are to be stretched minimum after 21 days of grouting.

8.12. HP, IP & LP module placement work can be taken up after 24 hours of grouting of the pedestal and base plates.

8.13. For individual pedestal and base plate, grout mixture should be poured in one lot only.

9. PLACEMENT OF HP MODULE IN POSITION

9.1. Ensure matching of all the four palms of the module where it is resting on the pedestals.

9.2. Ensure matching and parallelity of front and rear key block of the HP casing.

9.3. Assemble all four jacking screw of HPC and ensure their free movement.

9.4. Clean journals and coupling of the HP rotor.

9.5. Record journal dia, coupling hole sizes and spigot dia of HP rotor.

9.6. Lift module in level condition and place it in position by keeping it 3 to 5 mm toward front pedestal side.

9.7. During placement of module use temporary packers similar to permanent and additionally support it by four jacking screws.

9.8. Ensure load on all four packers with the help of some additional shims if required.

9.9. Install temporary radial and axial keys of the casing.

9.10. Prepare HP rotor for alignment (Ref. section 20 before placing the IP module.

10. PLACEMENT OF IP MODULE IN POSITION

10.1. Ensure matching of all the four palms of the module where it is resting on the pedestals.

10.2. Ensure matching and parallelity of front and rear key block of IP casing.

10.3. Assemble all four jacking screws of IP casing and ensure their free movement. If these jacking screw holes are provided with the bolts from factory then same are to be removed before placement of module.

10.4. Clean IP rotor on both sides including coupling and journal.

10.5. Record spigot /recess, journal dia, and coupling hole sizes.

10.6. Lift the module in level condition and place the module in position by moving about 7 to 8 mm towards generator end. Use temporary packers for placement of module in position and additionally support the module with jacking screws.

10.7. Ensure load on all four packers with the help of some additional shims if required.

10.8. Provisionally align the casing on front and rear pedestal bore. Install temporary radial and axial keys of the casing with some shims.

10.9. Prepare IP rotor for alignment (Ref. section 20).

NOTE: In case IP module is sent to site in disassembled condition, refer Instruction T1-08-0606G.

11. ASSEMBLY OF LP MODULE

This assembly can be divided in following sub assemblies:

11.1. Assembly of girder and end walls.

11.2. Assembly of LP inner inner and LP inner outer casing lower half.

11.3. Assembly / welding of LP outer casing.

Before starting assembly of LP casing in position, following works are also to be completed :

– Positioning and welding of LP casing centering pin of front and rear side.

– Positioning of key block of LP casing axial keys.

– Positioning of all internal of condenser.

12. POSITIONING AND WELDING OF LP CASING CENTERING PIN

Two nos. centering pins are to be located below LP front and LP rear pedestal. Necessary pipe along with two sq. end plates are already provided in the foundation to take the radial load of the LP casing:

12.1. Plumb the center line from LP front and LP rear pedestal bore on both side over the square plate of the foundation.

12.2. Establish accurate position of the pin and put a punch mark at a required height and mark a circle and a controlling circle over all the four sq. Plates.

12.3. Dia of the circle must be equal to pin dia. A template equivalent to pin dia has to be made for this purpose with about 20 mm thick plate and a welded pipe for using as an handle. The template dia must be very accurate and same may be made on machine.

12.4. Make precise hole with gas cutting/grinding to match template on all four embedded plate. Ensure that the template is fitted with minimum clearance and hole center are perfect as per marking.

12.5. Drill hole of about 10 mm dia on one of square plate of LP front and on one plate of LP rear for air venting to avoid cracks during welding.

12.6. Insert both the pins and carry out the welding as per laid down procedure. Before welding set correct axial position of the pins.

12.7. Insert key block on both the pins and weld their locking ring also. Ensure proper clearances in key block before welding of its locking ring.

12.8. Preheating of 200 degree Celsius or more to be achieved before any welding. Dye penetrate test on root run and after final welding is to be carried out.

13. ASSEMBLY OF GIRDER AND END WALL

13.1. Colour match side matching flange of girder with the surface plate.

13.2. Colour match seating flange of girder where it rests over the LP base plate.

13.3. Match and ensure parallality of axial key ways of girder.

13.4. Colour match side flanges of end wall.

13.5. Match and ensure parallality of key block of end wall.

13.6. Place left and right girder with carrier plate, spacer and lubrite packer on LP base plate.

13.7. Provisionally align and level the girders. Set height of the girder equivalent to machine center line maintaining catenary of the machine with the help of water level jar arrangement.

13.8. Assemble locking plate of the front and rear end wall to facilitate its assembly with the girders.

13.9. Assemble front and rear end wall with the girders and ensure perfect parting plane level during tightening.

13.10.Align, level LP outer casing and ensure contact of packers by colour matching/machining of spacer height.

13.11.Install LP casing radial and axial keys.

13.12.Assemble inner outer casing axial key blocks on left and right side of girder and dowel them.

13.13.Lock with tack welding all the vertical joint bolts.

13.14.Put a seal weld run between girder and end wall joint all around except on top face.

13.15.Weld girder and end wall parting plane joint with argon welding. Before welding make a V groove with the help of a chisel and allow the projection of material on surface. Do not make the groove by grinding.

13.16.Do colour matching with a surface plate on all four corner where argon welding have been carried out.

14. ASSEMBLY OF LP INNER INNER AND LP INNER OUTER CASING LOWER HALF

The LP inner inner casing lower half is received from factory in assembled condition with LP inner outer casing lower half.

14.1. Clean the casing and check all the threaded holes.

14.2. Do colour matching on all four corners of the casing where it rest over the girder.

14.3. Colour match all eight carrier plates of inner casing on both side.

14.4. Assemble all carrier plates on girder and do the colour matching with individual carrier plate.

14.5. Prepare Gusset plate of front and rear side with temporary radial keys for fitting in LP inner casing.

14.6. Level and lift LP inner outer casing and assemble/weld both the gusset plates with the help of some temporary support.

14.7. Lower the casing in position over the carrier plates fitted with spacer and lubrite packer.

14.8. Provisionally align the casing radially and axially.

14.9. Support the gusset plate with the help of screw jack (about 10-15 tons) on front and rear side by taking support from condenser stiffeners. Screw jack is to be unscrewed after box-up.

14.10.Adjust the height of the LP inner outer casing as per center line of the machine and then level it with the help of water level jar arrangement.

14.11.Ensure that all the eight packers have good contact. Loading of each packer is to be ensured.

14.12.Lower the casing by about 2 mm on all the eight packers with the help of shims for placement of LP rotor to avoid any fauling during placement of rotor.

14.13.Fit and weld all gusset plate stiffener pipes except pipe between LP inner outer casing and condenser. Do not make any weld connection between condenser and any of these stiffeners till neck welding of the condenser is over.

15. PLACEMENT OF LP ROTOR

15.1. Measure journal dia, spigot dia and coupling hole sizes.

15.2. Ensure centering of temporary bearing support in the LP front pedestal for placement of LP rotor.

15.3. Place LP rear bearing in position.

15.4. Prepare shaft seal compensator along with gaskets (Gasket to be installed in fully ring shape only ) and position them on LP rotor with the help of supplied supports of compensator.

15.5. Lift LP rotor with the supplied lifting beam in perfectly level condition and place it in position. During lowering of rotor ensure radial clearance with the help of long feeler gauges in the LP casing.

16. WELDING OF LP OUTER CASING

The welding of LP outer cover is to be carried out before placement of LP Rotor in position to avoid damage to the rotor.

16.1. Colour match and remove all high spots of the matching flange of the LP outer casing.

16.2. Ensure good contact between parted diffuser of LP front and LP rear cover.

16.3. Colour match and remove all the high spots of the parted diffuser/vertical face to ensure good contact with the compensator at a later stage.

16.4. Colour match and remove all burrs and high spots from parting plane of LP outer casing.

16.5. Side flange of LP front and rear cover are to be ensured in right angle to achieve good contact with their matching flanges.

16.6. Place LP front LP rear cover along with parted diffuser and ensure feeler tight joint after tightening the parting plane bolts. The joint must be feeler tight just after normal tightening of bolts. Do not over tighten parting plane bolts.

16.7. Ensure matching of parted diffuser face on both side of LP casing. If necessary colour matching may be carried out to achieve a feeler tight joint.

16.8. Drill/ream all the parting plane holes as per drawings and install all dowel pins.

16.9. After fixing of LP front and rear cover measure the dimension for positioning of both the center flanges. The dimension are to be recorded in such a way that there is no clearance after fitting of center flanges in position on both side with the LP front and rear cover. The center flanges are supplied in extra length on both sides from the factory and final length are to be maintained at site only.

16.10.Drill/ream dowel pin holes in center flanges and install all dowel pins in position. Ensure drilling and reaming of all dowel pin holes to equal depth.

16.11.Fit both the center pieces of the cover in position.

16.12.Achieve the fitting clearances for welding as per laid down procedure.

16.13.Weld/lock LP upper half flange with respect to lower half casing with the help of metal cleats to minimise the distortion during welding of LP cover. The cleats may be welded at an interval of about one meter distance.

16.14.Carry out the welding as per the following welding procedure.

17. Welding procedure

17.1. Tack weld the crowned seam joint. permanently welding approx. 100 mm at the generator end of the joint.

17.2. Opposite tack welded radial joint 2, permanently weld approx. 100 mm of the crowned seam joint, pos. 1, staggering the two weld ends to ensure a perfect transition when the crowned seam joint is finish welded.

17.3. Tack weld the crowned seam joint at regular intervals with a tack of 5T and pitch of 25T.

17.4. When welding radial joint 2, shell plates 1 & 2, tacked together, rest on but are not tacked to the retaining strip in the region of joint 1, so that any shrinkage occurring during welding of seam 2 is not obstructed.

17.5. The tacking & welding sequence applies for all shells courses.

17.6. Weld radial seam at TE according to welding sequence plan.

17.7. Align, adjust and tack weld radial seam at GE.

17.8. Weld radial seam at GE according to welding sequence plan.

17.9. Weld crowned seam joint.

17.10.Align shell courses on joint strips and tack weld,

17.11.Weld on joint strips from center & ends of shell plate.

17.12.Insert pins in top half casing, release top half casing and lift to insert and tack filler piece between joint strips.

17.13.Unbolt top half casing and lift in order to weld and finish – machine filler pieces in the region of the joint surface.

17.14.Check welds according to specifications.

18. ALIGNMENT AND COUPLING OF LP-IP & HP ROTOR

LP rotor is to be aligned on pedestal seal bore and LP inner outer casing is to be centralised in such a way that enough clearances are available to LP rotor, during alignment. Now this alignment activity of all the three rotor can be divided as below :

18.1. Preparation of HP rotor for alignment.

18.2. Preparation of IP rotor for alignment.

18.3. Preparation of LP rotor for alignment.

18.4. Alignment of LP-IP & HP rotors.

18.5. Reaming, honing of the coupling holes.

18.6. Balancing of coupling bolts weight.

19. PREPARATION OF HP ROTOR FOR ALIGNMENT

19.1. Align HP rotor with reference to front and rear pedestal seal bore reading. If required move complete HP module along with the rotor.

19.2. Fix temporary radial and axial key of the casing on both front and rear side of the casing. Remove HP front upper half transportation device.

19.3. Lift module by 0.20 mm on front side by putting additional shims in front packers.

19.4. Insert HP front bearing in position.

19.5. Reduce 0.20 mm shims gradually and ensure about 0.10 mm load on the rotor. If required further lower the front side of the module to achieve the loading on bearing by about 0.10 mm.

19.6. Remove HP front lower half transport device gradually and ensure no movement between HP casing and rotor. If necessary adjust shims of HP casing front packers.

19.7. During loading of bearing always ensure that the rotor is not fouling inside the casing with the shaft seals. This may be ensured by checking with feeler gauge also.

19.8. Check axial position of HP rotor in front side on left; right and top position from the rotor reference point to the HPC as given in the shop protocol.

19.9. Insert and load the bearing in HP rear end in similar way as carried out in case of HP front end and record axial position of rotor as per shop protocol.

19.10.Lock axially HP rotor with some fixture along with the arrangement of jacking screw for movement of rotor. This fixture may be mounted on rear pedestal. Before locking of rotor ensure axial position of the shaft.

19.11.Center HP shaft with reference to HP casing front and rear spigot. If necessary, move the casing readily to achieve the centering. A fixture can be fabricated at site for mounting the dial gauge on both the end of the rotor to check the centering of the shaft.

19.12.Use thick oil during rotation of shaft on the bearing.

19.13.Protect bearing from any of the dust particles. It is recommended to place upper half of bearing in position to avoid dust and any other damage to the shaft journal.

19.14.Realign the rotor shaft with respect to pedestal seal bore and if necessary adjust the shims below spherical support of the bearing.

19.15.Care should be taken during alignment that radial and axial clearances between rotor and casings does not get bridged.

19.16.Check HP rotor radial run out on journal and coupling.

19.17.Check axial run out on thrust collar and both the coupling faces of HP rotor.

19.18.Check axial float of the rotor. Compare values with shop protocol values. (Ref. T1-08-0802G). Deviations to be reported to Manufacturing Unit.

20. PREPARATION OF IP ROTOR FOR ALIGNMENT

The IP module is also to be prepared in line with the HP module. However as IP rotor is provided with one side bearing and opposite side is coupled with the HP rotor without a bearing, extra care is necessary during alignment of rotor in IP casing. The additional point which are to be taken care are explained below :

20.1. Place IP rotor rear end on bearing similar to the HP rotor and remove transportation device.

20.2. Provisionally align HP/IP rotors and couple on temporary bolts by moving both the modules. During coupling of the rotors, the transportation device of IP front end is also to be taken out.

20.3. Check axial position of rotor w.r.t. IP casing and adjust as per shop protocol.

20.4. Check centering of IP rotor front and rear end w.r.t. IP casing (similar to the HP rotor centering check).

20.5. Check float of the IP rotor. Compare values with the shop protocol values. (Ref. T1-08-0802G). During checking of float ensure HP casing is not fouling with HP rotor. If required HP casing may be moved axially for this purpose.

20.6. Check facial runout on IP rear coupling face and radial runout on journals and couplings.

21. PREPARATION OF LP ROTOR FOR ALIGNMENT

21.1. Provisionally align LP rotor in pedestal seal bore placing the front end of shaft on auxiliary bearing and rear end on bearing.

21.2. Align LP inner outer casing radially with the help of long feeler gauges and install temporary radial keys in the gusset plate.

21.3. Record all the radial and axial clearances of the LP casing without coupling the LP-IP rotor. Variation if any in radial or axial clearances are to be corrected/approved at this stage.

21.4. Remove shims from the front end of auxiliary bearing and keep rotor on lifting tackle.

21.5. Record radial run out of LP rotor coupling and journal and axial run out of the coupling faces of the both end.

21.6. Record float of the LP rotor by moving the LP inner outer casing lower half.

21.7. After ensuring the radial and axial run out of the LP rotor the LP inner outer casing can be boxed up. Parting plane bolts of LP inner-inner casing are to be heat tightened.

22. ALIGNMENT OF HP, IP AND LP ROTORS

22.1. Ensure radial and axial runout of all the three rotors are individually in order. If necessary individual rotor module can be taken out for correction of coupling face runout. Any variation on radial runout of rotor is to be referred to the factory.

22.2. Match coupling faces of two rotor as per the axial face reading of the rotor. Ensure that the higher point of the rotor coupling face and lower point of another rotor coupling face are matched together. This is to be compared with shop protocol also.

22.3. Preliminary align radially and axially all the three rotors and shift them in spigot along with the casing to avoid fouling of rotor inside the casing.

22.4. During alignment achieve left and right movement of the rotor with the help of shims in spherical / torus piece of the bearing. The up and down movement of the rotor is to be achieved with the help of shims in the cylindrical/spherical support of the bearing . The adjustment of shims in the bearing should be within the permissible limits only.

22.5. Ensure during alignment that the catenary of the shaft is maintained.

22.6. Check/record spigot clearance of HP-IP and LP-IP rotors by actually moving them in spigot.

22.7. Install four nos. supplied bolts along with one/two pins in HP-IP and LP-IP coupling. Hand tighten the coupling bolts by keeping a gap of > 1.00 mm in coupling faces for alignment.

22.8. Rotate the rotor system and record the coupling gap at 90 Deg. interval on left, right and top position. Ensure that the coupling, bolts and pins remain free while recording the gap of the coupling for the alignment purposes.

22.9. Check swing check value of the HP rotor with alternate bolts in position. The above value must be within the prescribed limit only otherwise a correction must be carried out at site in consultation with designer.

22.10.Ensure free movement of rotor on their bearing. Do not rotate the rotor if it is tight during its rotation.

22.11.Ensue that the coupling holes are properly aligned to avoid unnecessary enlargement of holes.

22.12.Ensure HP-IP-LP rotor radial run out after tightening with alternate clearance bolts. Release the couplings for reaming / honing of couplings.

22.13. In case of spring loaded TG decks, refer alignment procedure T1-08-0909G

23. REAMING / HONING OF COUPLING

23.1. Ensure that there is no disturbance on coupling during reaming/honing operation.

23.2. First ream/hone two opposite holes of the coupling and install two pins/bolts with sliding fit and then take up all other holes.

23.3. Enlarge coupling holes to the minimum possible diameter and try to make all the holes to same dia.

23.4. Ensure that the finished holes are straight and there is no banana shape. This can be ensured by checking hole with a straight ground finish pin having 0.02/0.03 mm clearance.

23.5. The length of the pin should be equal to the bolt length. In case, few holes have gone considerably over size during reaming/honing at site/works, do not enlarge all the holes. As a special case in such cases these few holes may be left as oversize.

23.6. Ensure that the holes during reaming/honing are perfectly finished as ground bore and size obtained should be within 0.005 mm. Ensure all the coupling bolts are fitted within 0.02/0.03 mm clearance with sliding fit and bolts are to be ground within an accuracy of 0.005 mm.

23.7. Coupling bolts are not to be hammered in the holes and these are to be fitted with thumb pressure only.

23.8. Do not decouple the coupling in any case without ensuring the fitting of all the coupling bolts.

24. BALANCING OF COUPLING BOLTS

After fitting the coupling bolts in all the holes these are to be balanced within 5 gms accuracy and an accurate balance which can take a load of about 20 kg. may be used. During balancing of coupling bolts following points are to be taken care.

24.1. Final balancing of the coupling bolts are to be done along with the coupling nut of individual bolt.

24.2. If all the coupling bolt hole sizes are same before/after reaming and honing then all the bolts can be kept of equal weight.

24.3. If necessary adjust the weight of the bolts by machining the metal from the bolt head.

24.4. When the holes of the coupling are of different sizes then it must be seen that whether excess enlargement have been done at site or works. In such cases if excess cutting have been done at site in a particular hole then coupling bolt with excess weight are to be used. The amount of excess weight must be equivalent to the excess enlargement of hole at site. If a particular hole of excess dia. is noticed from factory then it is assured that the particular rotor is balanced with excess dia hole and there is no need of providing excess weight bolt at site.

25. COLOUR MATCHING OF THRUST BEARING

After completion of reaming/honing and preliminary tightening of the coupling bolts, the colour matching of the thrust bearing pad have to be carried out with respect to the thrust collar of the HP Rotor. During colour matching a good contact on all the pads of front and rear side are to be ensured with respect to rotor collar by moving the rotor in +/- direction during its hand rotation. Following points are to be taken care during colour matching.

25.1. Thrust bearing must be axially locked with the help of axial keys during the colour matching of the pads. Axial keys to be fitted while finalizing the alignment of thrust bearing with rotor collar without pads.

25.2. Few drops of oil is to be put on journal portion of the thrust bearing during rotation of rotor to ensure that the oil is not entering in pad portion of the bearing.

25.3. Colour is to be applied on the thrust collar of the rotor.

25.4. If necessary move the spherical support of the bearing pedestal to ensure the equal thickness of the pads before fittment of axial keys of the bearing.

25.5. During moving of the spherical support in front or rear direction ensure that there is no left – right movement to the support otherwise that may cause misalignment of the bearing.

25.6. After colour matching of the thrust pad the axial zero position of the rotor is achieved and this can be taken for all other future reference for setting of axial position of HP, IP & LP casing.

25.7. HP, IP and LP lower casing are to be set axially after fixing the axial position of the rotor and their final axial keys can be installed at this stage.

26. ALIGNMENT OF HP, IP & LP CASING

After completion of colour matching of the thrust bearing pads the casing alignment work can be taken up. The following points are to be taken care while aligning HP, IP and LP casing.

26.1. The roll check have to be carried out in HP, IP and LP casing to ensure the correct radial clearances of the casing.

26.2. TG deck springs are to be kept in floating condition while recording the roll check of LP casing. However the roll check of HP/IP casing may be carried out before floating of TG deck for fitting of their radial keys but up and down roll check of HP/IP casings are to be done with TG deck in floating condition as per the procedure TS/ST/ 01/0008/00/96.

26.3. Ensure that there is no obstruction in the movement of LP inner casing due to welding of any of extraction piping. The one of the joint of extraction piping may be left free till completion of roll check of the casing.

26.4. The welding of steam inlet pipes between LP inner casing and LP girders are to be taken up after completion of roll check of the casing.

26.5. HP, IP and LP casing are to be fitted with final packers and axial key immediately after the roll check. During fitting of casing axial keys and palm packers ensure proper contact on lubrite coating of the keys/packers to avoid any damage of these coating during operation of the machine,

26.6. After completion of fitting of final keys and packers only the casing are to be cleared for further works of welding of various pipe lines.

26.7. The gland steam, balancing leak of lines, steam inlet and exhaust pipes are to be welded with HP casing after fitting of final axial keys and packers of the casing.

26.8. Center HP rotor w.r.t. casing front and rear spigots. Compare the readings with shop protocol and record the readings.

26.9. Offset center line of the HP, IP & LP casing w.r.t. respective rotor center line as per recommended logsheet.

26.10.Check/record LP diffusers centering readings after roll check of the casing.

26.11.Before roll check of LP casing all the stiffener pipe welding work must be completed. Refer T1-08-0909G.

27. FINAL Tightening of COUPLINGS

In case of spring loaded foundation after completing all other works the HP / IP , IP/LP , LP/GEN , GEN/EXCITER couplings are to be reopened and realigned after completing the reaming /honing . The rotors alignment are to be checked with TG deck in floating condition as per the laid down procedure. After checking of alignment /catenary the final couplings are to be tightened including their coupled run out and swing check of rotors on HP front and Exciter end of the shaft.

28. BOXING UP OF LP INNER INNER AND LP INNER OUTER CASING

The boxing up of LP inner inner and LP inner outer casing can be taken up before starting the alignment of HP-IP & LP rotor for coupling work. The following points are to be taken care before/during boxing up of these two casings.

28.1. Ensure matching of all the parting plane holes, fitting of cap nuts and accessibility of spanner .

28.2. Ensure feeler tightness of the parting plane joint of both the casing.

28.3. Check/record all the radial and axial clearances of the casing.

28.4. Ensure proper cleanliness of the LP inner inner and LP inner outer casing.

28.5. Ensure adequate clearance between LP inner inner casing and LP inner outer casing to avoid any obstruction during expansion of the LP inner casing inside the LP inner outer casing during operation of machines.

29. BOXING UP OF LP OUTER CASING

During the boxing up of the LP outer casing following points are to be taken care.

29.1. Roll check of LP inner casing including the fitting of key, packers etc. must be finished.

29.2. All the works must be finished inside the LP casing before boxing up of LP casing including LP extraction pipe line works.

29.3. Ensure matching of all parting plane holes and feeler tightness of the joint before boxing up of the casing.

29.4. Ensure feeler tightness of bursting diaphragm flange joint before boxing up of the casing.

29.5. Ensure proper assembly of parting plane rubber cord.

30. FINAL HORN DROP CHECK

After completing the welding of HP inlet, HP exhaust, IP inlet, IP exhaust and other piping of HP/IP casing the final horn drop readings are recorded as per the laid down procedure mentioned in the manual for horn drop check. However the IP casing horn drop is also to be recorded with IP inlet upper half pipe welded with casing alone.