Selective silica carryover

Selective silica carryover

Carryover of solids to turbine can be due to poor water chemistry, suspended solids in boiler water, excessive chemical dosing, highly alkaline boiler water, improper drum internal design, improper drum internal fit

up, high drum level operation.

-

Silica deposits can occur even if the mechanical carryover is completely taken care of.

-

Steam selectively picks up silica from boiler water, dissolves in steam, carries over to turbine, deposits on condensation.

At higher boiler operating pressures silica carryover is not controlled by drum internals.

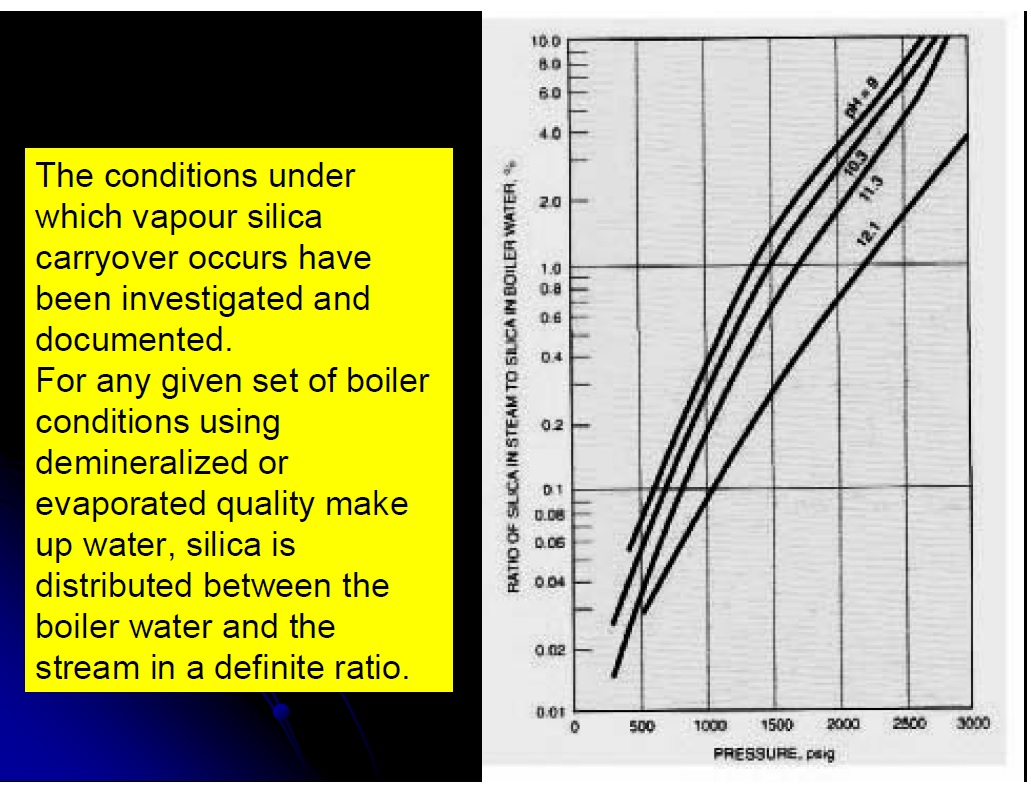

The carryover of silica is a function of operating pressure & Boiler water pH.

The blow down is set to maintain the allowable silica concentrations in the boiler water.

-

Blow down can be minimized if only make up water silica is treated /condensate contamination is controlled.

-

After silica enters the boiler water, the usual corrective action is to increase boiler blow down and then to correct the condition that caused the silica contamination.