Safety Valve

1.) Safety Valve

2.) Safety Valve Parts List (Name and Photo)

3.) Safety Valve Parts List (Material of Construction)

| 1 | Body Material | – | SA 216 Gr WCB |

| 2 | Bonnet Material | – | SA 216 Gr WCB |

| 3 | Disc Material | – | SA 565 Gr 616 (SS-422) |

| 4 | Spindle Material | – | SA 479 TP 316 |

| 5 | Spring | – | Alloy/ Tungsten Steel |

| 6 | Spring Washer | – | Carbon Steel |

| 7 | Retainer Ring | – | CF8M |

| 8 | Adjusting Ring | – | CF8M |

| 9 | Adjusting Ring pin Assy. | – | Steel |

| 10 | Gaskets | – | SS 316 |

| 11 | Hand Lever | – | Provided |

| 12 | GAG Arrangement (test gag) and Spring Cover | – | Provided |

| 13 | Applicable code | – | IBR / ASME SEC-1 |

| 14 | IBR Certificate | – | IBR FORM III-C & attachment 8 |

| 15 | Noise Level at 10 m distance | dBA | 126 |

| 16 | GA drawing | – | Provided |

| 17 | Weight | Kg | 70 |

4.) Safety Valve Specifications

| 1 | Location | – | HP Drum | S.H. outlet link |

| 2 | No. of Safety valves | Nos. | One | One |

| 3 | Fluid & State | – | Saturated steam | Super heated steam |

| 4 | Steam generation capacity | Kg/hr | 20200 | 33400 |

| 5 | Required relieving capacity | Kg/h | 10100 | 8350 |

| 6 | Relieving temperature | °C | 218.36 | 475 |

| 7 | Design temperature | °C | 230 | 490 |

| 8 | Set pressure | Kg/cm2 (a) | 24 | 22.5 |

| 9 | Set pressure range | Kg/cm2 (a) | 23.76 – 26.36 | 21.72 – 23.76 |

| 10 | System Design Pressure | Kg/cm2 (a) | 25 | 25 |

| 11 | Allowable Over pressure | % | 5 | 5 |

| 12 | Operating pressure | Kg/cm2 (a) | 20.5 to 23.5 | 18.5 to 22.5 |

| 13 | Blowdown | % | 2.5 to 5 | 2.5 to 5 |

| 14 | Imposed back pressure | Kg/cm2 (a) | Atmosphere | Atmosphere |

| 15 | Valve Type & Model No. | – | HSJ-46-IBR | HSJ-47-IBR |

| 16 | Actual relieving capacity | Kg/h | 12845 | 8758 |

| 17 | Valve inlet connection size & Rating | NB | 65 NB & #600 | 65 NB & #600 |

| 18 | Valve inlet end connection | – | Flanged end | Flanged end |

| 19 | Valve outlet connection size & Rating | NB | 100 NB & #150 | 100 NB & #150 |

| 20 | Valve outlet end connection | – | Flanged end | Flanged end |

| 21 | Orifice Type | – | K-Type | K-Type |

| 22 | Area | Sq. Cm. | 11.871 | 11.871 |

| 23 | Lift | mm |

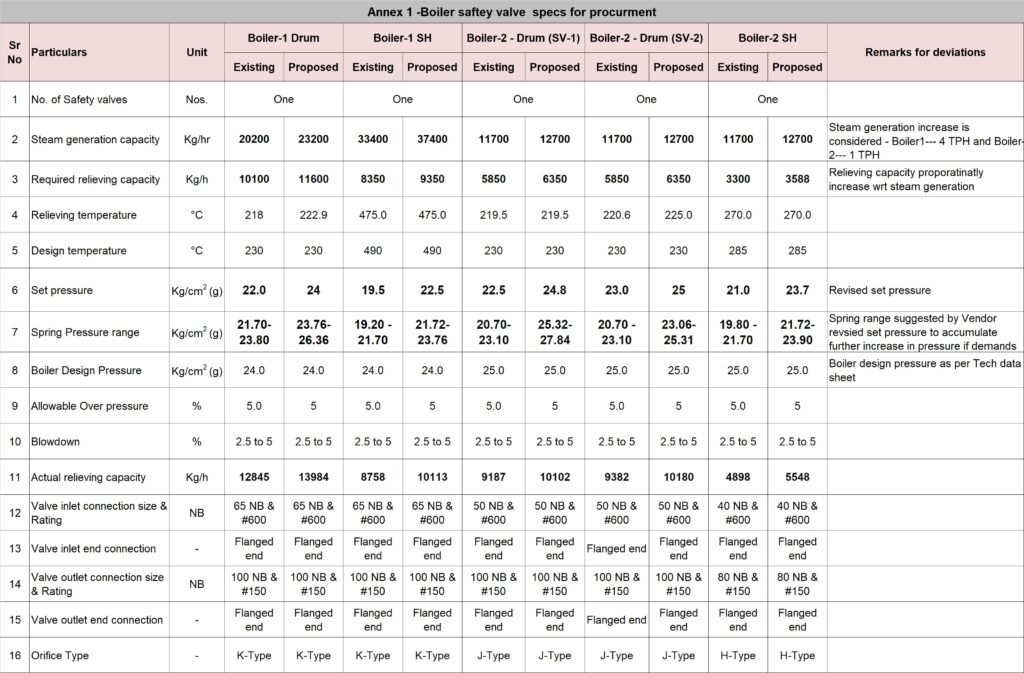

5.) Safety Valve Selection Parameters:-

If Boiler-1 & 2 steam generation likely to increase by 4 TPH and 1 TPH respectively So each new safety valves are considered for increase in relieving capacity approx. by 1-2 TPH as per below Annex 1.

In case safety valve set pressure is increasing, IBR formalities is also proposed.

6.) Safety Valve Details Required for IBR:-

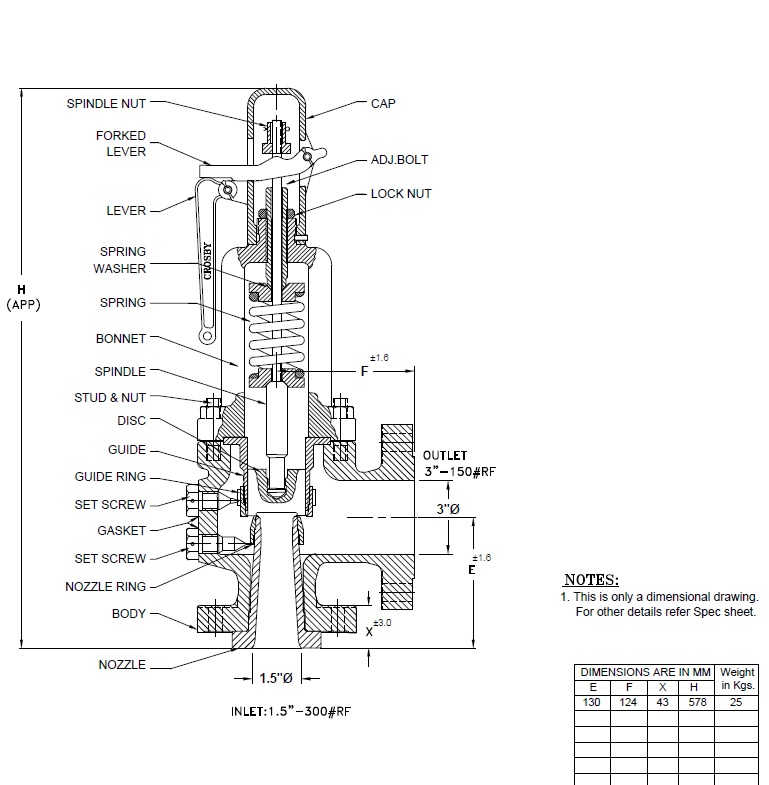

A.) Safety Valve Data Sheet

B.) Safety Valve Drawing

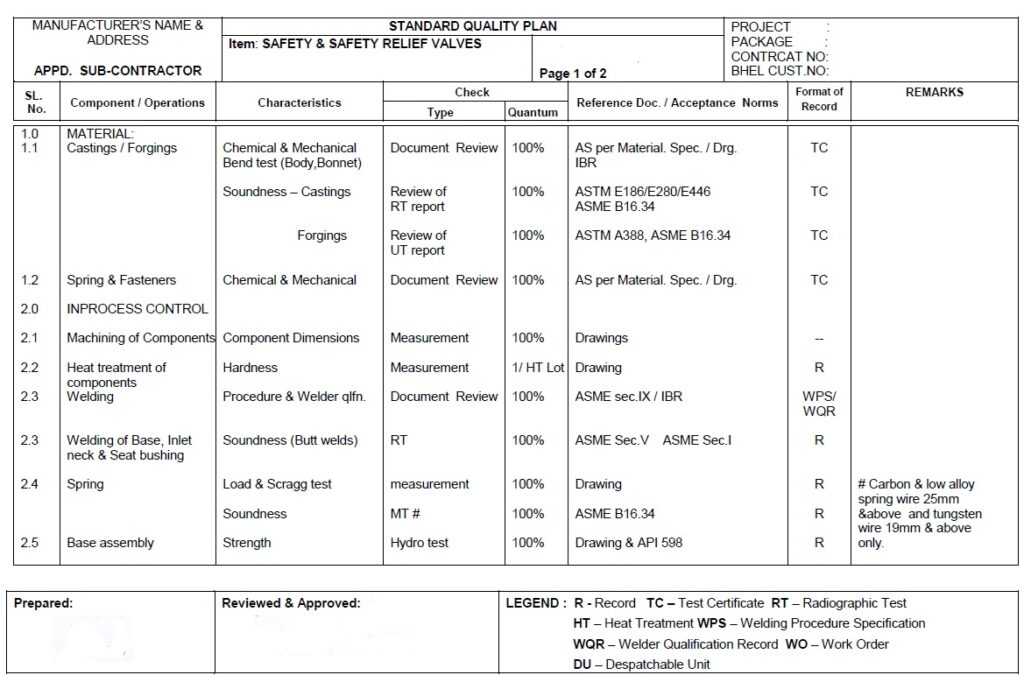

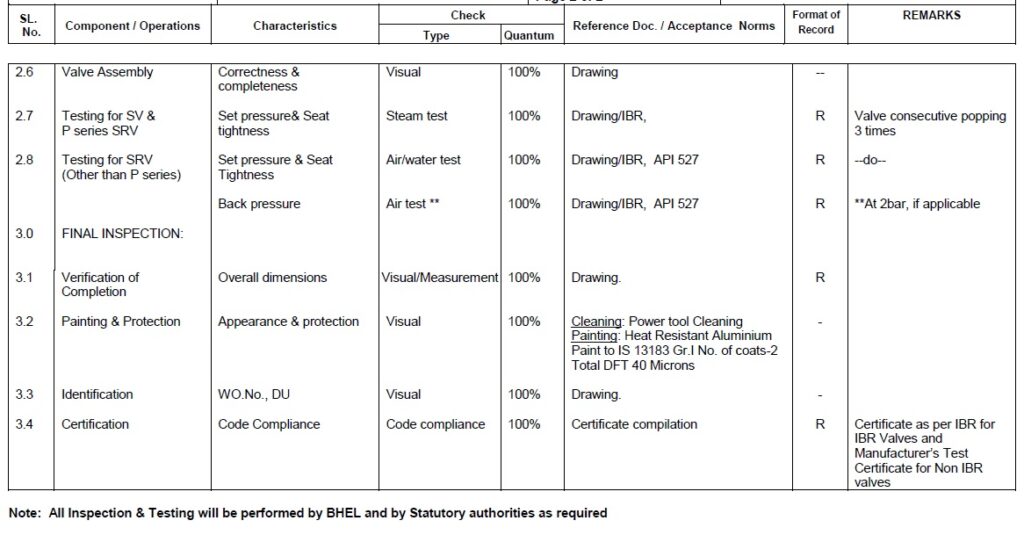

C.) Safety Valve Standard Quality Plan (SQP)

D.) Safety Valve test Certificate

good sharing