Cup lock system for boiler

1.) Introduction of Cup Lock Scaffolding System:-

Present System –

During boiler maintenance, we are using sky climbers and mechanical type of scaffolding systems. The sky climbers are used for accessible locations but it has the limitation that it cannot reach to all the locations so bulk of the job at different locations couldn’t be handled at a time and hence we are using mechanical type of scaffolding which is time consuming as well as safety is the concern.

Proposed system –

We propose to procure one set of Cup lock scaffolding for boiler combustor and cyclone, which is new-type of scaffolding and it will benefit us in following ways,

- It promises so many strengths like stable structure and heavy load bearing capacity so degree of safety is very high in comparison to present mechanical type of scaffolding.

- It will reduce the shutdown duration as it is easier to assemble and dismantle because it is based on the principle of joining the top and bottom cups. Estimated saving in shutdown duration reduction is by 2 days.

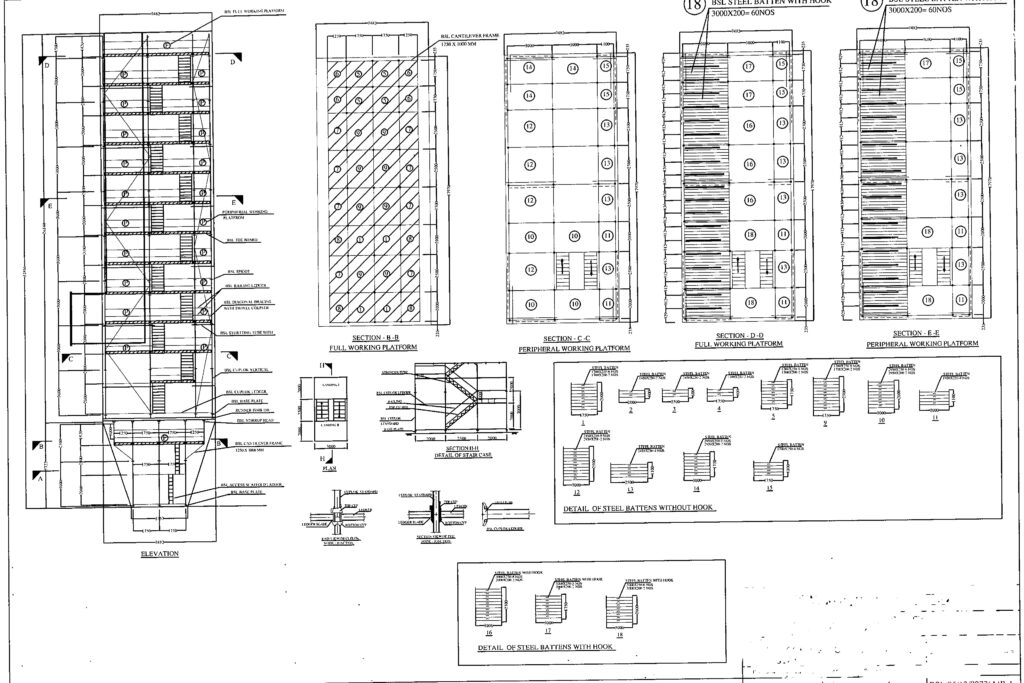

2.) Drawings:-

3.) Parts Name:-

1.) Main Tower [Scaffolding]

2.) Full working platform at Section B-B at 1 levels.

3.) Full working platform at Section D-D at 1 levels

4.) Peripheral working platform at Section C-C at 1 levels

5.) Peripheral working platform below coils @ 2.0M for hopper portion, Section – E-E at 9 levels

6.) STAIRCASE ARRANGEMENT.

4.) Item List:-

For Plan Area -7482X17970mm and Height of Scaffolding – 31.8 Mtr, The list of materials required for the above area will be as under :-

1.) Cuplok Standard [40mm NB `Medium’ class with cups @ 500mm c/c] yst-210

2.) Cuplok Ledger [ 40 mm NB “Light” class ] yst-210

3.) Spigot with nuts & bolts [ Round ]

4.) 36 mm dia Adj. Base Plate with 50x50x8mm 450mm Adj.

5.) Diagonal Bracing Tube, 40 mm NB `Medium’ class, painted, plain end in the random length of 6.0m [+–75mm]

6.) Strutting Tube, 40 mm NB `Medium’ class Painted, plain end in the length of # 3.5 m [+–75 mm ]

7.) Swivel Coupler 40 x 40 mm NB[Electro-plated]

8.) Right Angle coupler 40x40mm NB [Electro-plated]

9.) Runners ISMB-150 RM

10.) Omega Transom

11.) Cantilever Frame.

12.) Steel Scaffold Board [16G sheet, Press Bent with anti-skid dimples with stiffener]

13.) Steel Scaffold Board (With Hook) [16G sheet, Press Bent with anti-skid dimples with stiffener]

14.) Cuplok Ledger as railing [40mm NB `Light’ class tube] yst-210

15.) Toe Board 16G 30 mm deep complete with nuts & bolts]

16.) Connecting Tube.

17.) Right Angle coupler 40x40mm NB[Electro-plated]

5.) layher Scaffolding Photos:-

6.) Analysis Layher Allround Scaffolding (Modula Scaffold) Vs Cuplok/H-Frame/Tube & Coupler Scaffolding Systems:-

Layher will supplying a system scaffold called All-round, which is a ring lock systems. The All-round system is a further development of the Cuplok//H-Frame/Tube & Coupler Scaffold system with extended possibilities. All-round scaffolding convincingly comes in with an unmatched range of advantage: unbeatably fast assembly, persuasive economic arguments and an extensive range of series-produced accessories. Connections in this quick to assemble and spanner less scaffolding system make a unique combination; providing structural strength immediately on assembly and subsequent ultimate force transmission while offering a choice of automatically right angled or splayed connections with unrivalled safety right from the start.

All steel components of Layher Scaffolding systems are Hot-Deep Galvanized with longer life-cycle than painted scaffolding.

A lot more factors, like yield stress, number of standards, spacing of standard and capacity of platform (decks) determine the load bearing capacity of a complete structure. Usually, the requirements for the life load of scaffolding starting from load requirements Layher designs a suitable construction using the parts from the All-round Scaffolding systems.

The loadings on the scaffoldings shall comply with the appropriate requirements of relevant Indian standards regarding loading on temporary structures and scaffoldings (As per IS 2750-1964). All scaffoldings have been adequately stiffened; both longitudinally and transversely to take up horizontal loading.

As per IS 806-1968, it has been clearly shown that higher grade of tube (Grade Yst 320) gave higher Axial stress in tension, bending stress, minimum shear stress and minimum bearing stress.