Heat Exchanger

1.) Introduction

2.) Heat Transfer and Fluid Flow

3.) Types of Heat Exchangers

4.) Heat Exchangers and Systems

5.) Summary

1.) Introduction

Heat transfer is an important function of many industrial processes.

Transfer heat from one process to another.

2.) Heat Transfer and Fluid Flow

- Conduction

- Convection

- Radiant

- Laminar

- Turbulent

1.) Conduction:-

Heat energy is transferred through solid objects

Molecules absorb heat energy from a hotter source and then vibrate, so transfer the energy from the hot side to the cooler side

What is more, there are free electrons moving in the metal, so metal have better capability of conduction

2.) Convection:-

Convection occurs in fluids when warmer molecules move toward cooler molecules

The movement of the molecules sets up currents in the fluid that redistribute heat energy

The result is that the energy is equally distributed

3.) Radiant Heat Transfer:-

Heat is conveyed by electromagnetic waves

Radiant heat transfer is a line-of-sight process

Radiant heat transfer is not used in a heat exchanger

4.) Laminar Flow:-

Liquid flowing are in parallel fashion

Laminar flow usually exists at low flow rate

Laminar flow promotes the development of static film, which acts as an insulator

5.) Turbulent Flow:-

Turbulent flow is random movement or mixing of fluids

Turbulent flow allows molecules of fluid to mix and absorb heat more readily than does the laminar flow

Turbulent flow decreases the thickness of static film, increasing the rate of heat transfer

3.) Types of heat exchangers

- Double-pipe heat exchanger

- Shell and tube heat exchanger

- Plate and frame heat exchanger

- Spiral heat exchanger

- Pipe coil exchanger

- Air-cooled heat exchangers

1.) Double-pipe heat exchanger:-

A double-pipe exchanger has a pipe inside a pipe

The outside pipe provides the shell. And the inner pipe provides the tube

The warm and cool fluids can run parallel flow or counter current, because it is more efficient

Flow rates are very low in a double-pipe heat exchanger

The chemical processing industry commonly uses hairpin heat exchangers

Hairpins are typically rated at 500psig shell side and 500 psig tube side

Fins can be added to the internal tube’s external wall to increase heat transfer

Advantages:

Its excellent capacity for thermal expansion

It is easy to install and clean

Its modular design makes it easy to add new sections

Replacement parts are inexpensive and always in supply

Disadvantages

It is not as cost effective as most shell and tube exchangers

it requires special gaskets

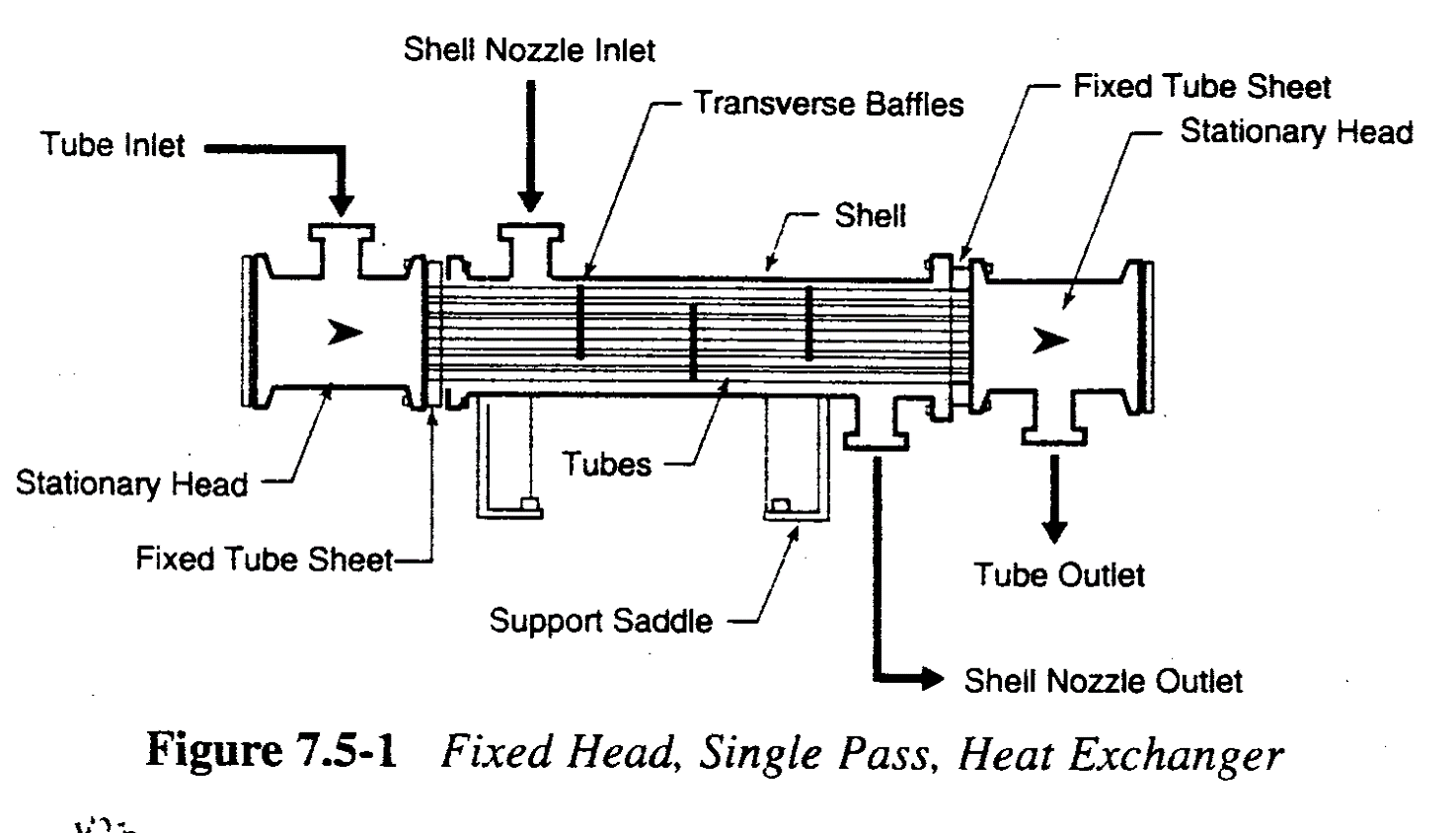

2.) Shell and Tube Heat Exchangers

The shell and tube heat exchanger is the most common style found in industry

As the tube side flow enters the exchanger, flow is directed into tubes that run parallel to each other. these tubes run through a shell that has a fluid passing through it

Heat energy is transferred through the tube wall into the cooler fluid

Heat transfer occurs primarily through conduction and convection

A.) Shell and Tube Heat Exchanger—Shell

In most cases, the shell is designed to withstand the greatest temperature and pressure condition

The shell is the largest single part of the heat exchanger

The shell can be classified as single-pass, double-pass, split flow, double split flow, divided flow, cross-flow

B.) Shell and Tube Heat Exchanger—Tube

Tube can be plain or dinned

Plain tubes are commonly used in fabrication

Finned tube are starting to make an impact, fins can be located externally or internally

Tube materials include brass, carbon, …

C.) Shell and Tube Heat Exchanger—Tube Sheet

Tube sheets are often described as fixed or floating, single or double

Tube sheets have carefully drilled hole, the ends of the tubes in a heat exchanger are fixed by rolling, welding, or both

Double tube sheets are used to prevent tube side leakage of highly corrosive fluids

Engineering specifications take into account thermal tube expansion

If the tube sheet is welded or bolted to the shell, it is called fixed

If the tube sheet is independently secured to the tube head and is allowed to move freely inside the shell, it is called floating

D.) Shell and Tube Heat Exchanger—Baffle

Baffles provide the framework to support and secure the tubes and prevent vibration

The baffle layout increases or decreases fluid and directs flow at specific points

Tube side baffles are built into the heads to direct tube side flow

In multi pass exchangers, cost goes up with each pass, provide adequate fluid velocities to prevent fouling and to control heat transfer

E.) Shell and Tube Heat Exchanger—Tie Rod

Tie rods and concentric tube spacers keep the baffles in place and evenly spaced

Each hole in the baffle plates is 1/64” larger than the tube’s outside diameter

F.) Shell and Tube Heat Exchanger—Nozzles and Accessory Part

Nozzles and accessory part

Inlet and outlet nozzles are sized for pressure drop and velocity considerations

Thermowells, pressure indicator connections, safety and relief valves, product drains, vents, block valves and control valves

G.) Shell and Tube Heat Exchanger—Fixed Head

In a fixed head, single pass shell and tube heat exchangers, the tubes are connected to two tube sheets which are firmly attached to the shell

in the multi pass Shell and tube heat exchangers, the baffle added to the channel head and the lack of a tube side outlet on the discharge head

Temperature differential is less to 200℃

H.) Shell and Tube Heat Exchanger—Floating Head

One side of the tube bundle is fixed to the channel head, the other side is unsecured

Floating head exchangers, with their high cross-sectional areas(fins), are designed for high temperature differentials and high flow rate, produces the highest heat transfer efficiency

I.) Shell and Tube Heat Exchanger—U-Tube

The tube sheet connects a series of tubes bent in a U shape, the ends of the tubes are secured to the tube sheet

The total number of tubes is limits

Large temperature differentials

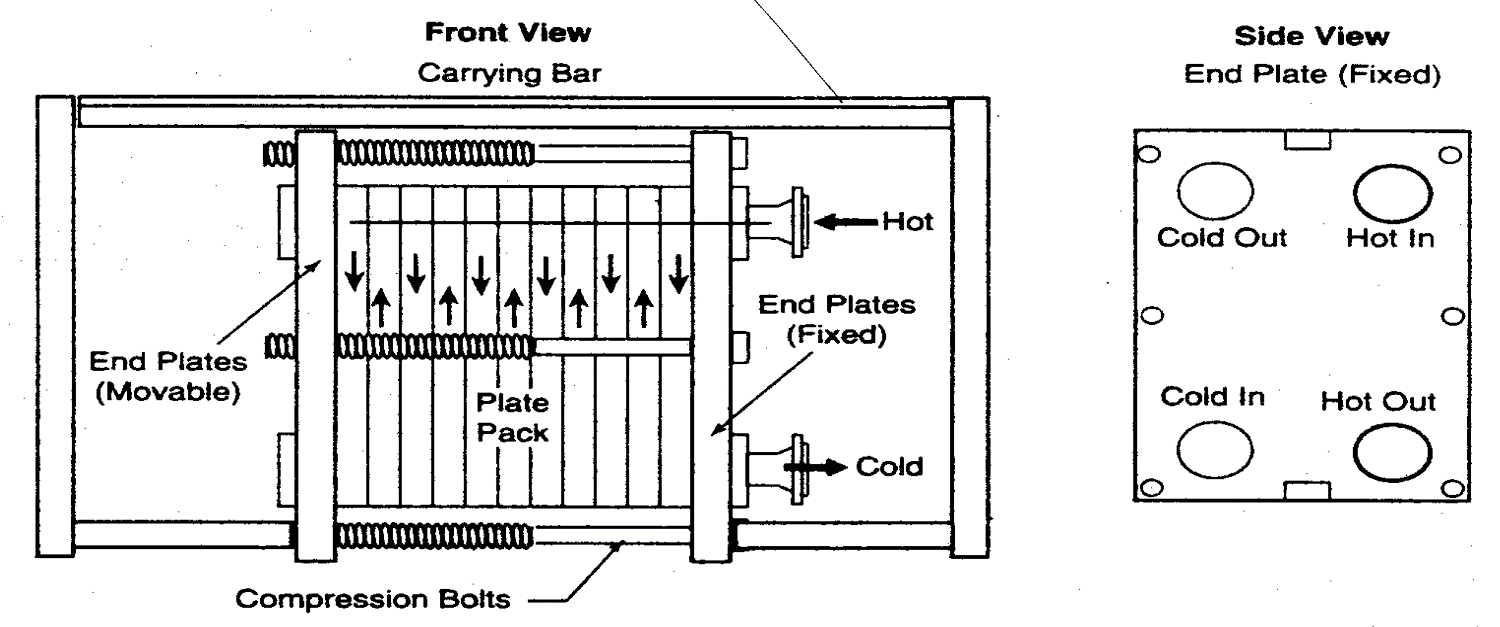

3.) Plate and Frame Heat Exchanger:-

It consist of a series of gasketed plates, sandwiched together by two end plates and compression bolts

Plate and Frame Heat Exchanger

Easy to disassemble and clean and distribute heat evenly so there are no hot spots

Plates can easily be added or removed

Low fluid resistance time, low fouling, high heat transfer

4.) Spiral Heat Exchanger:-

Spiral heat exchangers are characterized by a compact concentric design that generates high fluid turbulence

Type 1: spiral flow on both sides

Type 2: spiral flow-cross-flow

5.) Pipe Coil Exchanger:-

Pipe coils are submerged in water or sprayed with water to transfer heat

This type of operation has a low heat transfer coefficient and requires a lot of space

6.) Air-Cooled Heat Exchanger:-

Air-cooled heat exchangers provide plain or dinned tubes connected to an inlet and return header

Air is used as the outside medium to transfer heat away from the tubes

Fans are used in a variety of arrangements to apply forced convection for heat transfer coefficients

Provides a 40℃ temperature differential between the ambient air and the exiting process fluid

Air-Cooled Heat Exchanger

simple to construct and cheaper to maintain

Cannot fouling or corrosion

Low operating costs and superior high temperature removal

Limited in use

High outlet fluid temperature and high initial cost of equipment

In cases of loss of containment, they would be fire or explosion

4.) Heat Exchangers and Systems

Heat Exchangers and Systems—Parallel and Series Flow

in series flow, the tube side flow in a multi pass heat exchanger is discharged into the tube side flow of the second exchanger

In parallel flow, the process flow goes through multiple exchangers at the same time

Heat Exchangers and Systems—Cooling Towers

The system consists of a cooling tower, heat exchanger, pump

Cooling water is pumped into the shell side of a heat exchanger and returned (much hotter) to the top of the cooling tower

5.) Summary

The methods of heat transfer are conduction, convection, and radiation

The fluid flow are laminar and turbulent

The best conditions for heat exchangers are large temperature difference, high heating or coolant flow rates, large cross-sectional area of the exchanger, and others, so which heat exchanger is choose, it depends.