GAS METAL ARC WELDING

1.) GAS METAL ARC WELDING (GMAW)

1.) Gas metal arc welding (GMAW), is sometimes referred to as

◦Metal inert gas (MIG) welding or

◦Metal active gas (MAG) welding

2.) GMAW is a semi-automatic or automatic arc welding process in which a continuous and consumable wire electrode and a shielding gas are fed through a welding gun.

3.) A constant voltage, direct current power source is most commonly used with GMAW.

2.) GMAW Operation / Principal

3.) Equipment’s for GMAW

4 wheel wire drive unit

GMAW Welding Gun

1.Handle

2.Moulded phenolic insulation (shown in white)

3.and threaded metal nut insert (yellow)

4.Shielding gas nozzle

5.Contact tip

6.Nozzle

Arc Welding Gun Nomenclature

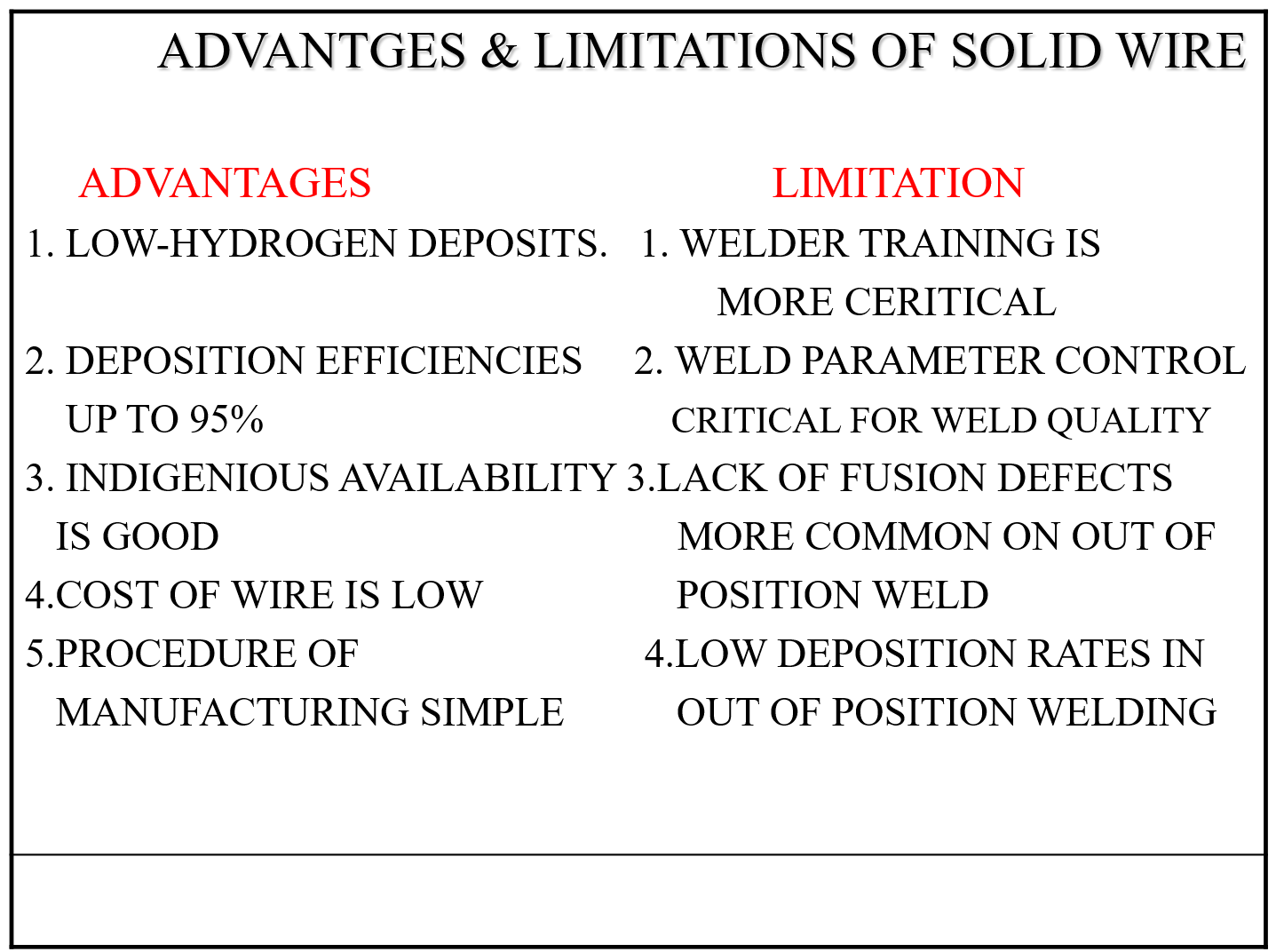

4.) GMAW Advantages and Limitation:-

5.) GMAW –Mode of Transfer

There are four primary methods of metal transfer in GMAW. They are:

◦Globular

◦Short-circuiting

◦Spray, and

◦Pulsed-spray

GMAW – Metal Transfer Mode

Each transfer mode has distinct properties, advantages and limitations.

The mode of transfer is determined by a number of factors:

◦Magnitude, type and polarity of welding current

◦Electrode diameter

◦Electrode composition

◦Electrode extension and

◦Shielding gas composition

6.) GMAW -Process variables

The following are some of the process variables that affect weld penetration, bead geometry and overall weld quality.

Welding Current (Electrode feed speed)

Polarity

Arc voltage (Arc length)

Travel speed

Electrode extension

Electrode orientation

Shielding gas