Loading...

Loading...

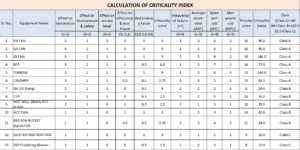

CALCULATION OF CRITICALITY INDEX FOR CRITICAL EQUIPMENT IDENTIFICATION AS PER CLASS A, B AND C FOR PROCESS /MANUFACTURING INDUSTRY….

| EQUIPMENT | TOTAL CRITICALITY INDEX SCORE | % CONTRIBUTION TO TOTAL CRITICALITY INDEX SCORE | NO OF EQUIPMENTS | INDIVIDUAL CRITICALITY INDEX RATING |

| Class – A | 2474.5 | 30.80 | 26 | >=60 |

| Class – B | 5096.93 | 63.45 | 128 | 22.5 to <60 |

| Class – C | 461.75 | 5.75 | 34 | <22.5 |

| Total | 8033.18 | 100.00 | 188 | |

| Criteria for Criticality Index | ||

| Criticality index is based on following elements: | ||

| 1 | Effect on Generation – (G) | |

| Effect on the element | Score | |

| No significant consequences on generation due to failure | 1 | |

| Generation loss < 20% | 2 | |

| Generation loss < 50% | 3 | |

| Unit tripping | 4 | |

| Station tripping | 5 | |

| 2 | Effect on Environment and Safety – (E) | |

| Effect on the element | Score | |

| No effect on Environment and Safety | 1 | |

| Very minor effect | 2 | |

| Failure leads to an accident or significant | ||

| impact on environment | 3 | |

| 3 | Effect on Service Level – (S) | |

| Effect on the element | Score | |

| Failure will not affect the work of succeeding equipment | 0 | |

| Failure will affect the work of succeeding equipment | 1 | |

| 4 | Effect on Efficiency & Aux Power (A) | |

| Effect on the element | Score | |

| No effect on Efficiency & Aux Power | 0 | |

| Very minor effect | 0.5 | |

| Failure leads to a major effect on Efficiency & Aux P | 1 | |

| 5 | Redundancy Factor | (RF) |

| Effect on the element | Score | |

| If there is no standby unit for the failed equipment | 1 | |

| If the number of standby unit is 1 | 0.5 | |

| If the number of standby unit is 2 | 0.33 | |

| Criticality Score = (G+E+S+A) X RF | ||

| Where: | ||

| G | = Effect on Generation | |

| E | = Effect on Environment and Safety | |

| S | = Effect on Service Level | |

| A | = Effect on Efficiency & Aux Power | |

| RF | = Redundancy Factor | |

| 1 | Frequency of Failure- (FF) | |

| Effect on the element | Score | |

| Once per year or rare | 1 | |

| Twice in a year or once per six months | 2 | |

| Four times in a year or once in ¾ months | 3 | |

| Frequent failures or more than 4 failures in a year | 4 | |

| 2 | Average Down Time- (ADT) | |

| Effect on the element | Score | |

| If Down Times is 0 to ½ Day | 1 | |

| If Down Times is 1/2 to 1 Days | 2 | |

| If Down Times is 1 to 3 Days | 3 | |

| If Down Times is 3 to 7 Days | 4 | |

| If Down Times is more than 7 Days | 5 | |

| 3 | Spare Parts Cost – (SPC) | |

| Effect on the element | Score | |

| Cost of spares up to Rs 25,000/- | 1 | |

| Cost of spares from Rs 25,000/- to 50,000/- | 2 | |

| Cost of spares from Rs 50,000/- to 1,00,000/- | 3 | |

| Cost of spares from Rs 1,00,000/- to 5,00,000/- | 4 | |

| Cost of spares from Rs 5,00,000/- to 10,00,000/- | 5 | |

| Cost of spares from Rs 10,00,000/- to 50,00,000/- | 6 | |

| Cost of spares from Rs 1,00,00,000/- to 5,00,00,000/- | 7 | |

| Cost of spares above Rs 5,00,00,000/- | 8 | |

| 4 | Man Power Cost (MPC) | |

| Effect on the element | Score | |

| If Cost of Man Power to attend the | ||

| failure is Rs 10,000/- or less | 1 | |

| If Cost is form Rs 10,000/- to 1,00,000/- | 2 | |

| If Cost is above Rs 1,00,000/- | 3 | |

| Priority Score = (FF x SPC) + (ADT x MPC) | ||

| where | ||

| FF | = Frequency of Failure | |

| SPC | = Spare Part Cost | |

| ADT | = Average Down Time | |

| MPC | = Man Power Cost | |