Boiler Feed Pump

1.) Types of Boiler feed pumps in BTPS:-

There are of two Types

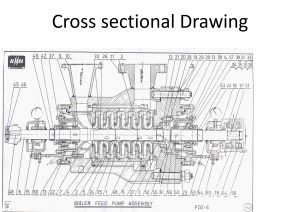

1.1) 150KHI and 200KHI. 150KHI pumps operate at 3000RPM with 9/10 stages directly coupled to motor.

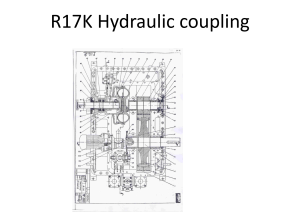

1.2) 200KHI pumps operate with R17K hydraulic coupling speed range being 3600-4500 rpm, six stage pump.

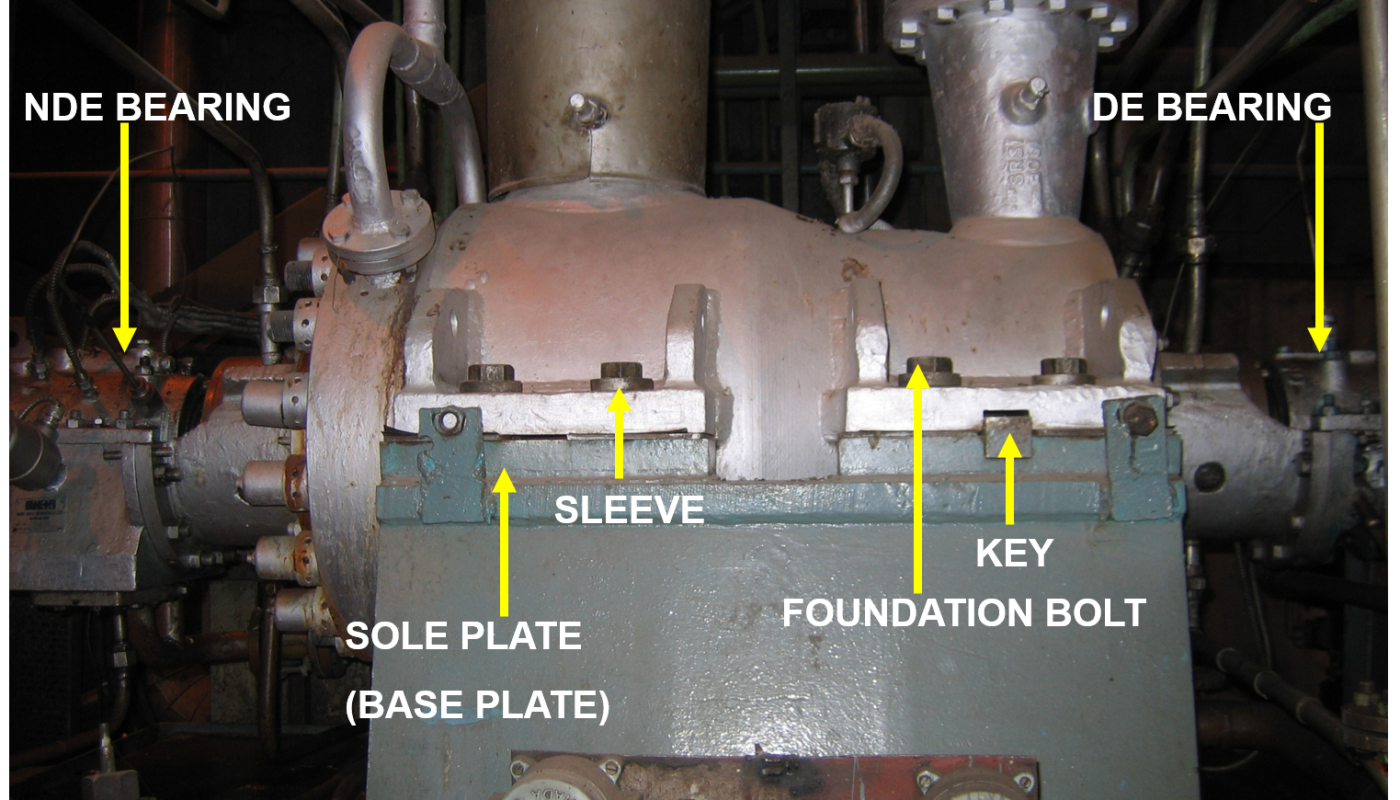

The BFP’s of KHI design , needs 40% of assembly of the pump to be done at site. The centering of the rotating parts w.r.t. stationary parts , axial positioning of rotor, clearances required for thrust balancing of rotor, seal compression, journal bearing matching and clearance setting , and thrust bearing positioning are to be done at site.

2.) Assembly of Boiler Feed pump:-

2.1) Insertion of cartridge

- The body seat thoroughly checked for cracks

- Barrel tie rods tightened equally ensured by measuring suction side depth

- Key block to cartridge clearances adjusted

- Discharge side diffuser to HP bush clearances adjusted

2.2) HP cover tightening

- HP cover seat checked

- HP bush made eccentric 0.4mm

- HP bush fitted on HP cover

- HP cover fitted on barrel

- Initially four bolts tightened

- Bolts tightened after electric heating

- Equal clearances of HP cover and Barrel checked

2.3) Centering of rotor

- LP cover fitted on HP cover both side

- Bearing housing fitted on both side

- Bottom bearings matched with housing both side

- Rotor centering done

- Centering with LP cover checked, adjusted again, rotor centered, LP cover centering done again. Free rotation checked.

- Run-out at journals checked

- Reaming done with taper reamer

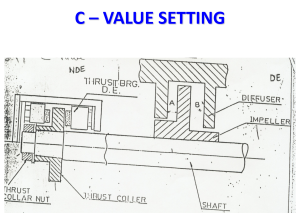

2.4) Axial positioning

- C value adjusted to ensure axial positioning

- Lapping of balancing disc with bearing disc

- Rotor at C value check free rotation

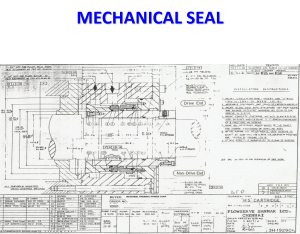

2.5) Setting seal compression

- Seal compression checked when rotor at C value

- Range of 10.6 to 11.5

- After tightening seals check rotation

- Correct size o rings to be used

2.6) Thrust bearing

- Thrust pads checked for free movement

- Blue matching of disc with pads

- Disc clearance with housing checked

- Float of bearing checked

- K value of pump set to ensure gap between balancing disc and bearing disc.

- Rotation checked at k value.

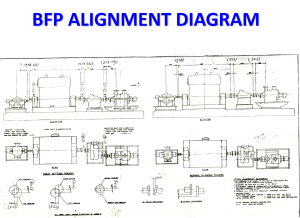

2.7) Alignment

- All flanges tightened before alignment

- Individual shaft run-out checked

- Full size shims used

- Non-magnetic shims used

- Number of shims reduced

- After alignment and coupling run-out at bearing journal checked

For pumps in service

- Centering checked once in three years

- Balancing chamber checked every year

- Seals checked every year

- Bearings checked every year

- Run-out at journals most important parameter for old pumps.

For old pumps

- Suction side impeller clearance good indication of cartridge health

- During checking LP cover and stuffing box hydro-test conducted

- Float checked compared with original

- Free rotation checked

- During parallel operation check flow of pumps

2.8) Hydraulic couplings

- In service for 25 years

- Checking of bearings started after dismantling

- Worn out bearings replaced

- If gear teeth broken coupling replaced

- If grinding noise comes from gears M/S Voith recommend to replace, but repair cost being high allowed to run.

- Problem of AOP not taking load, solved by replacing NRV of AOP suction

- The pressure of oil in working oil cooler is less than cooling water pressure. So tapping of water should be after motorised valve for BFP air cooler.

3.) Cooling water problems of BFP:-

- BTPS cooling water is corrosive and with lot of plastics and other foreign materials

- Cooling lines get chocked, headers get deposits and erosion

- Coolers get checked and tubes blocked

- Cooler end plates erosion and consequent oil leakages

- Lub. oil temperatures run high

- Seal water cooler get chocked

- Bearing temperatures run high

Cooling water problems- Solutions adopted

- Header flushing at regular intervals

- Coolers fitted with flushing valves

- Tube plates replaced with SS plates instead of brass plates

- Replacement of coolers after definite intervals

- Limited success with filters

4.) Alignment of Boiler Feed Pump:-

BFP ALIGNMENT –TYPES OF MISALIGNMENT:

- ANGULAR,

- PARALLEL OR OFFSET, AND

- COMBINATION

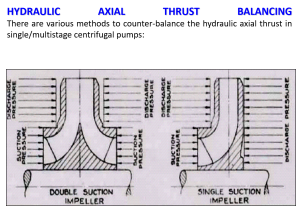

5.) BALANCING OF HYDRAULIC AXIAL THRUST:-

HYDRAULIC AXIAL THRUST IN PUMPS – SINGLE STAGE

- HYDRAULIC AXIAL THRUST:

Hydraulic axial thrust is the summation of unbalanced forces acting on the Impeller shrouds in the axial direction.

- DOUBLE-SUCTION PUMPS:

Theoretically, a double – suction impeller is in hydraulic axial balance with the pressures on one side equal to and counterbalancing the pressures on the other. But, in practice, this balance may not be achieved for the following reasons:

The suction passages to the two suction eyes may not provide equal or uniform passages to the two sides.

HYDRAULIC AXIAL THRUST-BALANCING DEVICES:-

- MULTISTAGE PUMP WITH SINGLE SUCTION IMPELLERS FACING IN ONE DIRECTION (TANDEM):

The total theoretical hydraulic thrust acting toward the suction end of the pump will be the sum of the individual impeller thrusts. To balance the axial thrust and to reduce the pressure on the shaft seal adjacent to the last stage impeller some form of hydraulic balancing device must be used. This hydraulic balancing device may be one of the following:

- Balancing Drum,

- Balancing Disc, and

- Combination of Disc & Drum.

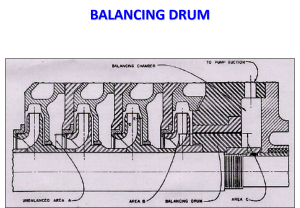

BALANCING DRUM

- The Balancing Chamber at the back of the last stage Impeller is separated from the Pump interior by a Drum keyed/screwed to the Shaft and therefore rotates with the Shaft.

- The Drum is separated by a small radial clearance from the stationary portion of the Balancing Drum Bush that is fixed in the Discharge Cover.

- The Balancing Chamber is connected either to the Pump suction or to the Deaerator, thus the back pressure in Balancing Chamber is slightly higher than the suction pressure.

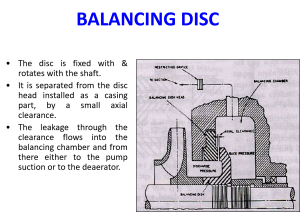

BALANCING DISC

- The back of the balancing disc is subject to the balancing chamber back pressure whereas the disc face experiences a range of pressures, which vary from discharge pressure at its lowest diameter to back pressure at its periphery.

- The inner and outer diameters are chosen so that the difference between the total force acting on the disk face and that acting on its back will balance the impeller axial thrust.

- If the axial thrust of the impellers exceed the thrust acting on the disc during operation, the later is moved toward the disc head, reducing the clearance between the disc & its head. The amount of leakage through the clearance is reduced so that the friction losses in the leakage return line are also reduced, lowering the back pressure in the balancing chamber. This automatically increases the pressure difference acting on the disc and moves it away from the disc head, increasing the clearance.

- Now, the pressure builds up in the balancing chamber and the disc is again moved toward the disc head until an equilibrium is reached.

- A restricting orifice is installed in the leakage return line which increases back pressure when leakage past the disc increases beyond normal.

- The disadvantage of this arrangement is that the pressure on the shaft seal is variable – a condition that will shorten the life of the seal and is therefore to be avoided.

- The use of a balancing disc without a thrust bearing is generally limited to small pumps only.

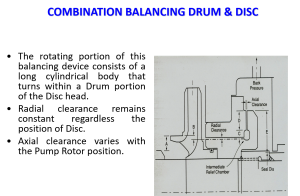

COMBINATION BALANCING DRUM & DISC

- The following thrusts are developed by this device acting in conjunction with the last stage impeller:

Toward the Discharge End – last stage suction pressure X area A + the intermediate pressure X area C + the average pressure across the axial clearance X area D.

Toward the Suction End – last stage discharge pressure X area B + the back pressure X area E.