Steam Turbine Gland Seal / Fins Clearances

Steam Turbine Gland Seal / Fins Clearances, Role for Performance Improvement by Improvement in Clearances, Different Types of turbine Clearances for Improve Heat Rate / Efficiency which Includes Importance of Seals, Testing method of seal clearances (1) Medical tap method (2) lead Wire Method (3) Butt Clearance This is for Turbine Performance Improvement by Improvement in Heat Rate / Efficiency also Balancing of the Thrust.

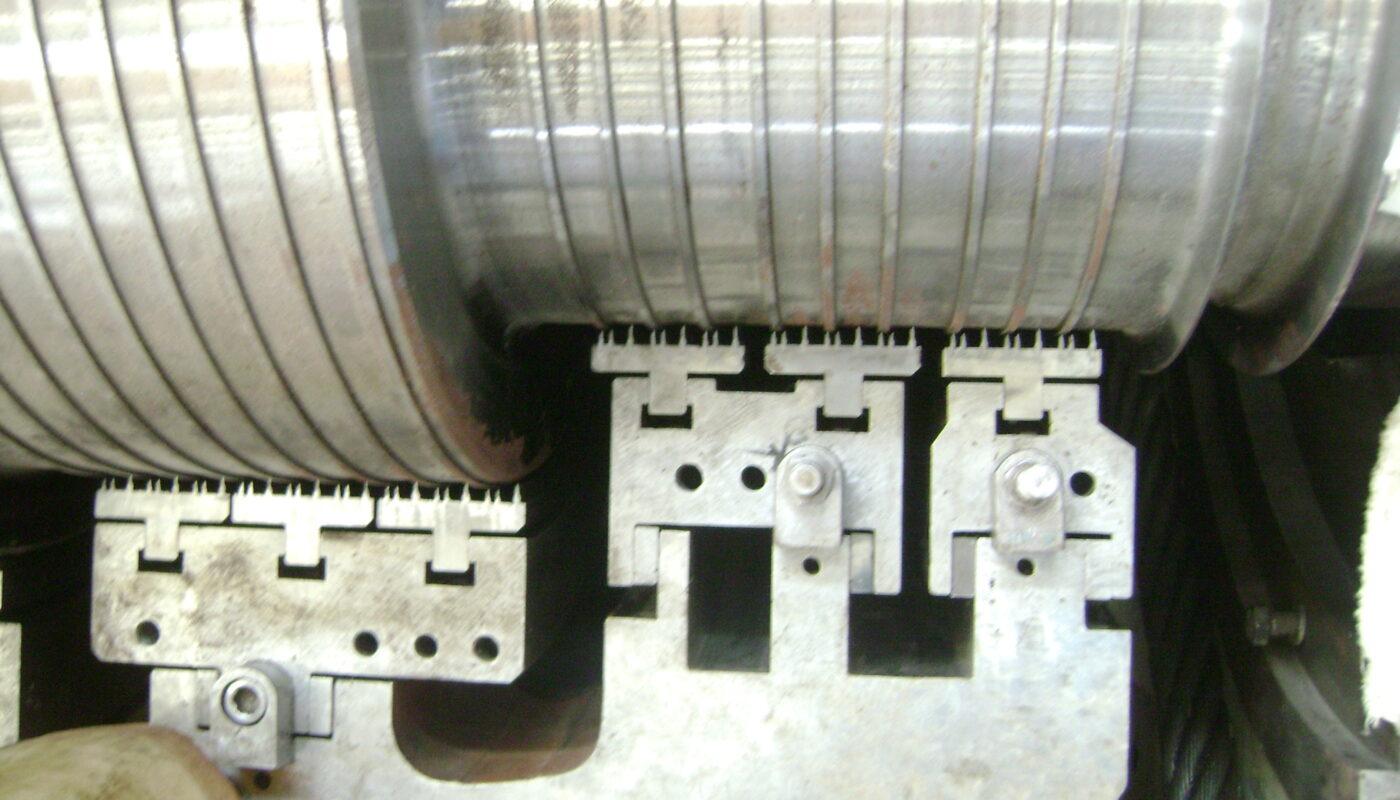

Steam Turbine Gland Seal / Fins Details

1.) Gland sealing system:

The function of the shaft seal is to avoid the steam leakages from HP ,IP turbine shafts & avoid Air ingressment to LP turbine.

2.) Important of seals:-

- Sealing fins reduces the leakage’s of steam through inter stage and turbine ends there by leading to high efficiency and better Heat Rate

- They also result in balancing of the Thrust.

- Sealing fins deemed to be reject/damaged

- When the desired clearances have increased

- When their Knife edge is lost or found bend

- When they are broken at the intermittent places.

3.) Types of Gland Seal Clearances:-

4.) Role for Performance Improvement by Improvement in Clearances:-

Objective of performance overhauling:-

| Unit- Area | Expected impact on Heat Rate | Expected overall gain (Rs. In Lacs / Annum) |

| Turbine (Improvement in clearances ) | 27 Kcal / Kwh | 323 |

5.) Advanced Sealing Technology For Steam Path Efficiency Improvement Above OEM Design:-

6.) Method / Procedure for Seal fin Clearance (Seal Fin Cutting)

For better efficiency and trouble free operation Seal fins clearances is to be kept strictly as per design values.

After the centering activity is over we can start Elevation Transfer in the TOP Internals and can also start the Seal fin cutting of the Inter stage and Gland sealing of the Bottom Internals.

1.) White medical adhesive tape Method

2.) Lead Wire Method

3.) Butt Clearance

4.) Top Half Diaphragm Lift

- During Overhauling, Even if the Old Seals are used, never use the old Helical/ Flat Springs

- Butt Clearances between sealing segments should be strictly as per Design values.